Cilindri elettromeccanici

Serie 6E

Taglie 32, 40, 50, 63, 80, 100

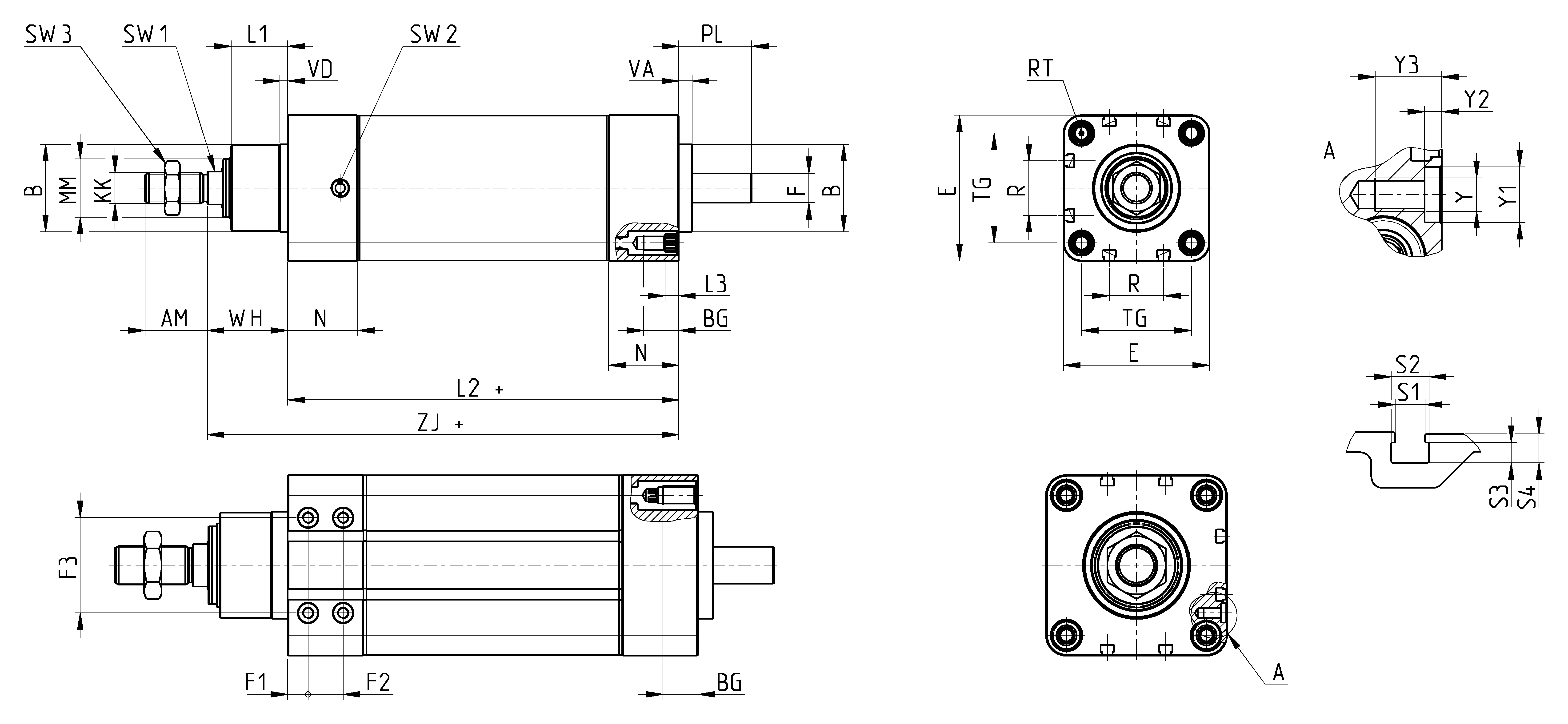

I cilindri Serie 6E sono attuatori meccanici lineari a stelo in cui il moto rotatorio generato da un motore è convertito in un movimento lineare tramite l’utilizzo di una vite a ricircolo di sfere. Disponibile in 6 taglie, la Serie 6E ha le dimensioni basate sullo standard ISO 15552 ed è quindi possibile l’utilizzo di accessori di fissaggio utilizzati per i cilindri pneumatici.

I cilindri sono muniti di un magnete che rende possibile l’utilizzo di sensori a scomparsa esterni (Serie CST e CSH), grazie ai quali possono essere eseguite funzioni di homing o letture di extracorsa. La Serie 6E è dotata di specifici kit di interfaccia con i quali è possibile eseguire il collegamento del motore sia in linea che in parallelo.

Elevate precisioni e semplicità di montaggio fanno sì che la Serie 6E sia la soluzione ideale in svariate applicazioni, specialmente nei sistemi multiposizione.

I cilindri sono muniti di un magnete che rende possibile l’utilizzo di sensori a scomparsa esterni (Serie CST e CSH), grazie ai quali possono essere eseguite funzioni di homing o letture di extracorsa. La Serie 6E è dotata di specifici kit di interfaccia con i quali è possibile eseguire il collegamento del motore sia in linea che in parallelo.

Elevate precisioni e semplicità di montaggio fanno sì che la Serie 6E sia la soluzione ideale in svariate applicazioni, specialmente nei sistemi multiposizione.

Serie

Accessori

Non sono presenti codici vendibili online

Se hai inserito Filtri prova a cambiarli oppure cerca nella tab "Configurator"

addtocart.popup.message.success

La quantità da lei richiesta è confermata solo parzialmente

Il prodotto {0} è gia presente nel tuo carrello in quantità {1}. Puoi aggiornare la quantità dal carrello.

Il prodotto non è attivo

Non è stato possibile aggiungere il prodotto al carrello a causa di stock insufficente

La quantità deve essere maggiore di zero

La quantità minima per il prodotto {0} è {1}

La quantità massima per il prodotto {0} è {1}

Il prodotto {0} è ordinabile in multipli di {1}

Non è possibile aggiungere il prodotto con codice {0} a questo carrello

Si è verificato un errore, riprova più tardi o contatta l'assistenza clienti

| Costruzione | Cilindro elettromeccanico con vite a ricircolo di sfere |

| Design | A profilo con viti autoformanti basato su ISO 15552 |

| Funzionamento | Attuatore multi-posizione con movimento lineare ad alta precisione |

| Taglie | 32, 40, 50, 63, 80, 100 |

| Corse min - max | 100 ÷ 1500 mm |

| Funzione antirotazione | Con pattini antifrizione in tecnopolimero |

| Montaggio | a flangia anteriore / posteriore, con piedini, con cerniera anteriore / posteriore / snodata |

| Montaggio motore | In linea e in parallelo |

| Temperatura di lavoro | 0°C ÷ 50°C |

| Temperatura di stoccaggio | -20°C ÷ 80°C |

| Grado di protezione | IP40 / IP65 |

| Lubrificazione | Non necessaria. Sul cilindro viene eseguita una pre-lubrificazione. |

| Gioco assiale max | 0,02 mm |

| Ripetibilità | ± 0,02 |

| Ciclo di lavoro | 100% |

| Max angolo di rotazione | ± 0,4° |

| Utilizzo con sensori esterni | Cave su tre lati per sensori modelli CSH e CST |

addtocart.popup.message.success

La quantità da lei richiesta è confermata solo parzialmente

Il prodotto {0} è gia presente nel tuo carrello in quantità {1}. Puoi aggiornare la quantità dal carrello.

Il prodotto non è attivo

Non è stato possibile aggiungere il prodotto al carrello a causa di stock insufficente

La quantità deve essere maggiore di zero

La quantità minima per il prodotto {0} è {1}

La quantità massima per il prodotto {0} è {1}

Il prodotto {0} è ordinabile in multipli di {1}

Non è possibile aggiungere il prodotto con codice {0} a questo carrello

Si è verificato un errore, riprova più tardi o contatta l'assistenza clienti

Esempio di codifica

| 6E | 032 | BS | 0200 | P05 | A | P |

| 6E | SERIE | |

| 032 |

TAGLIA 032 = 32 040 = 40 050 = 50 |

063 = 63 080 = 80 100 = 100 |

| BS |

TRASMISSIONE BS = vite a ricircolo di sfere |

|

| 0200 |

CORSA 100 ÷ 1500 mm |

|

| P05 |

PASSO DELLA VITE P05 = 5 mm P10 = 10 mm P16 = 16 mm (solo per taglia 40) P20 = 20 mm (solo per taglie 50, 80, 100) |

P25 = 25 mm (solo per taglia 63) P32 = 32 mm (solo per taglia 80) P40 = 40 mm (solo per taglia 100) |

| A |

TIPO COSTRUTTIVO A = standard con dado stelo |

|

| P |

VERSIONE P = IP65 ( _ _ _ ) = stelo più lungo di _ _ _ mm |

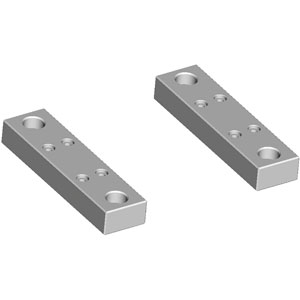

GUIDE MOD. 45NUT, 45NHT, 45NHB

| 45 | N | UT | 050 | A | 0100 |

| 45 | SERIE |

| N |

VERSIONE N = standard |

| UT |

FUNZIONAMENTO UT = guida ad "U" con bronzine HT = guida ad "H" con bronzine HB = guida ad "H" con manicotti a sfere |

| 050 |

TAGLIA 032 = 32 040 = 40 050 = 50 063 = 63 |

| A |

CARATTERISTICHE MATERIALI A = corpo alluminio anodizzato - colonne guida inox AISI 420B rullato per 45UT e 45HT - colonne guida acciaio C50 temprato per 45HB |

| 0100 | CORSA in mm |

Guide MOD. 6ENHT

| 6EN | HT | 080 | A | 0100 |

| 6EN | MODELLO |

| HT |

FUNZIONAMENTO HT = guida ad "H" con bronzine |

| 080 |

TAGLIA 080 = 80 100 = 100 |

| A |

CARATTERISTICHE MATERIALI A = corpo alluminio anodizzato - colonne guida inox AISI 420B rullato per 45UT e 45HT - colonne guida acciaio C50 temprato per 45HB |

| 0100 | CORSA in mm |

| Taglia | AM | B | BG | E | F | F1 | F2 | F3 | KK | L1 | L2+ | L3 | MM | N | R | RT | PL | SW1 | SW2 | SW3 | TG | VA | VD | Y | Y1 | Y2 | Y3 | WH | ZJ | S1 | S2 | S3 | S4 | peso corsa 0 [g] | peso corsa [kg/m] |

| 32 | 22 | 30 | 16 | 46,5 | 8 | - | - | - | M10x1,25 | 20 | 125 | 5,5 | 18 | 26 | 13 | M6 | 21 | 10 | G1/8 | 17 | 32,5 | 6 | 4 | - | - | - | - | 30 | 155 | 5,4 | 6,8 | 3,65 | 5 | 1175 | 3,77 |

| 40 | 24 | 35 | 16 | 55,4 | 10 | - | - | - | M12x1,25 | 22 | 142 | 5,5 | 22 | 27 | 13,5 | M6 | 24 | 13 | G1/8 | 19 | 38 | 6 | 4 | - | - | - | - | 33 | 175 | 5,4 | 6,8 | 3,65 | 5 | 1395 | 5,30 |

| 50 | 32 | 40 | 16 | 64,9 | 12 | - | - | - | M16x1,5 | 26 | 173 | 5,5 | 25 | 36 | 16 | M8 | 30 | 17 | G1/8 | 24 | 46,5 | 7 | 4 | - | - | - | - | 38 | 211 | 5,4 | 6,8 | 3,65 | 5 | 2280 | 6,03 |

| 63 | 32 | 45 | 16 | 75 | 15 | - | - | - | M16x1,5 | 29 | 201 | 5,5 | 30 | 36 | 28 | M8 | 38 | 17 | G1/8 | 24 | 56,5 | 7 | 4 | - | - | - | - | 42 | 242,5 | 5,4 | 6,8 | 3,65 | 5 | 3500 | 9,77 |

| 80 | 40 | 55* | 18 | 93 | 19 | 10,5 | 18 | 49 | M20x1,5 | 35 | 211 | - | 40 | 39 | 30 | M10 | 39 | 22 | G1/4 | 30 | 72 | 8 | 8 | M6 | 10 | 3 | 12 | 49 | 260 | 5,4 | 6,8 | 3,65 | 5 | 6440 | 13,70 |

| 100 | 40 | 65* | 18 | 115 | 24 | 13 | 18 | 62 | M20x1,5 | 38 | 232 | - | 50 | 44 | 40 | M10 | 42 | 22 | G1/4 | 30 | 89 | 8 | 8 | M8 | 12 | 3 | 16 | 51 | 283 | 5,4 | 6,8 | 3,65 | 5 | 10725 | 20,50 |

1-16/30 risultati

Italia

Italia

Download Catalogo

Download Catalogo

.jpg)

.jpg)

.jpg)

.jpg)