Series

Rear trunnion (ball joint) - R-41-100

Rear trunnion - R-41-125

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

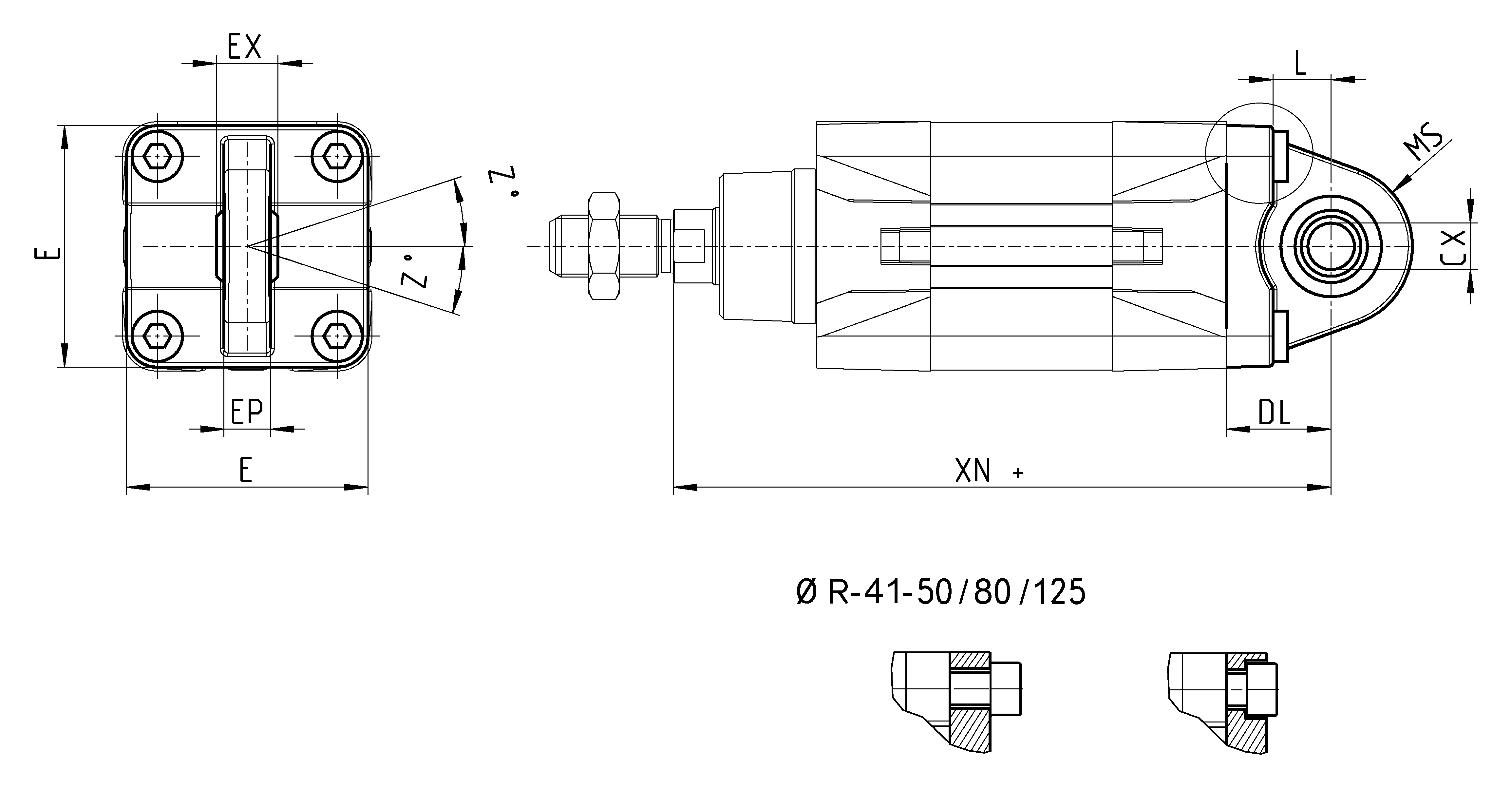

| Mod. | Ø | CX | L | DL+ | XN+ | MS | E | EX | EP | Z | Torque force |

| R-41-32 | 32 | 10 | 12 | 22 | 142 | 16 | 45 | 14 | 10,5 | 4 | 5 Nm |

| R-41-40 | 40 | 12 | 15 | 25 | 160 | 19 | 52 | 16 | 12 | 4 | 5 Nm |

| R-41-50* | 50 | 12 | 15 | 27 | 170 | 21 | 62,5 | 16 | 12 | 4 | 10 Nm |

| R-50 | 50 | 16 | 16 | 27 | 170 | 21,5 | 65 | 21 | 15 | 4 | 10 Nm |

| R-41-63 | 63 | 16 | 20 | 32 | 190 | 24 | 75 | 21 | 15 | 4 | 10 Nm |

| R-41-80* | 80 | 16 | 24 | 36 | 210 | 28 | 92 | 21 | 15 | 4 | 15 Nm |

| R-80 | 80 | 20 | 22 | 36 | 210 | 28,5 | 95 | 25 | 18 | 4 | 15 Nm |

| R-41-100 | 100 | 20 | 25 | 41 | 230 | 30 | 115 | 25 | 18 | 4 | 15 Nm |

| R-41-125 | 125 | 30 | 30 | 50 | 275 | 40 | 140 | 37 | 25 | 4 | 20 Nm |

| R-3E-32 | 32 | 10 | 12 | 22 | 18 | 45 | 14 | 10,5 | 4 | 4 | - |

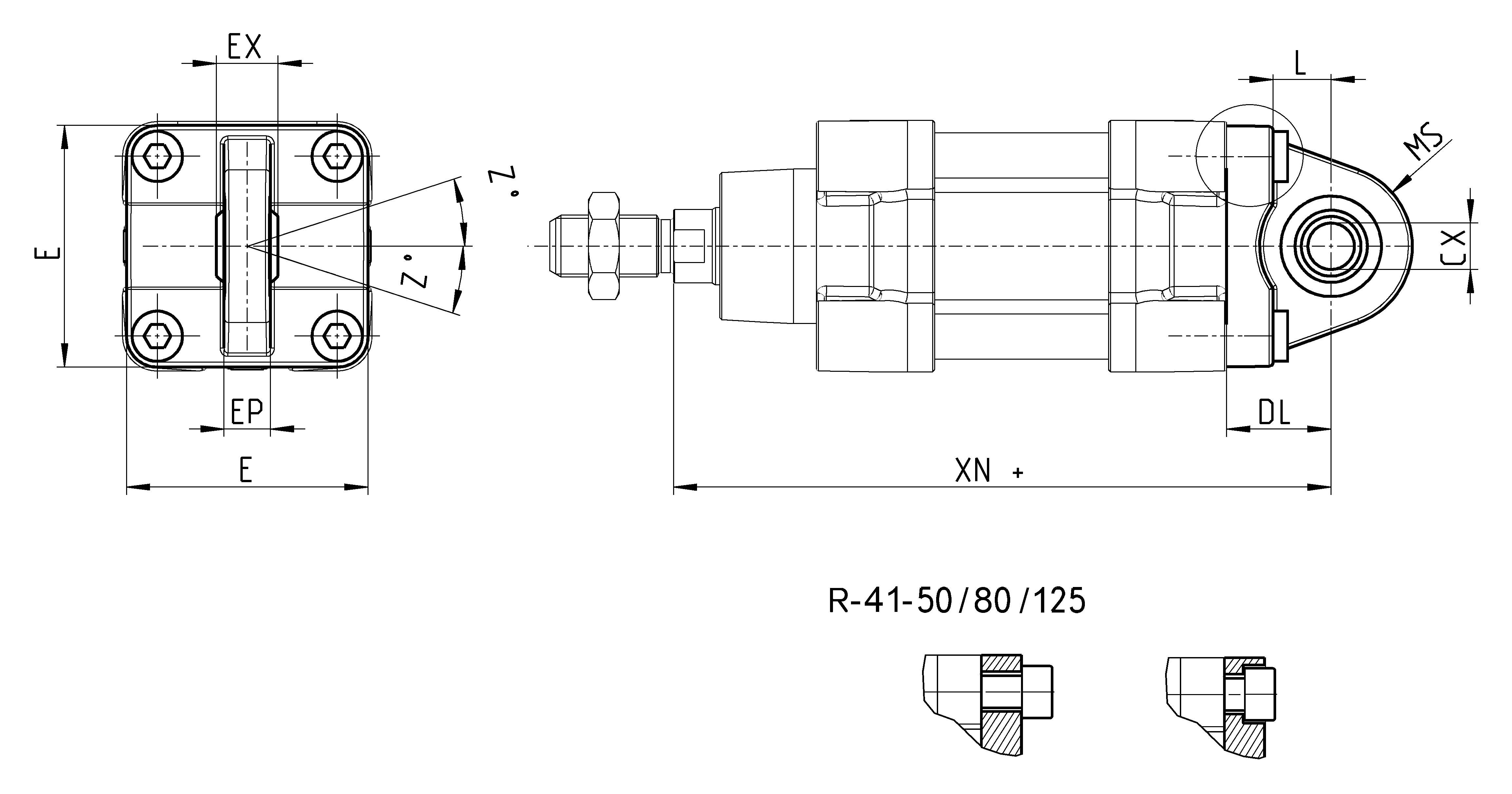

| Mod. | Ø | ØCX | L | DL+ | XN+ | MS | E | EX | EP | Z | Torque force |

| R-41-32 | 32 | 10 | 13 | 22 | 142 | 16 | 45 | 14 | 10.5 | 4 | 5 Nm |

| R-41-40 | 40 | 12 | 16 | 25 | 160 | 19 | 52 | 16 | 12 | 4 | 5 Nm |

| R-41-50* | 50 | 12 | 15 | 27 | 170 | 21 | 62.5 | 16 | 12 | 4 | 10 Nm |

| R-50 | 50 | 16 | 16 | 27 | 170 | 21,5 | 65 | 21 | 15 | 4 | 10 Nm |

| R-41-63 | 63 | 16 | 21 | 32 | 190 | 24 | 75 | 21 | 15 | 4 | 10 Nm |

| R-41-80* | 80 | 16 | 24 | 36 | 210 | 28 | 92 | 21 | 15 | 4 | 15 Nm |

| R-80 | 80 | 20 | 22 | 36 | 210 | 28,5 | 95 | 25 | 18 | 4 | 15 Nm |

| R-41-100 | 100 | 20 | 27 | 41 | 230 | 30 | 115 | 25 | 18 | 4 | 15 Nm |

| R-41-125 | 125 | 30 | 30 | 50 | 275 | 40 | 140 | 37 | 25 | 4 | 20 Nm |

| Mod. | Ø | CX | L | DL+ | XN+ | MS | E | EX | EP | Z | Torque force |

| R-41-50* | 50 | 12 | 15 | 27 | 170 | 21 | 62.5 | 16 | 12 | 4 | 13 Nm |

| R-50 | 50 | 16 | 16 | 27 | 170 | 21.5 | 65 | 21 | 15 | 4 | 10 Nm |

| R-41-63 | 63 | 16 | 20 | 32 | 190 | 23 | 75 | 21 | 15 | 4 | 13 Nm |

| R-41-80* | 80 | 16 | 24 | 36 | 210 | 28 | 92 | 21 | 15 | 4 | 19 Nm |

| R-80 | 80 | 20 | 22 | 36 | 210 | 28.5 | 95 | 25 | 18 | 4 | 15 Nm |

| R-41-100 | 100 | 20 | 25 | 41 | 230 | 30 | 115 | 25 | 18 | 4 | 22 Nm |

| R-41-125 | 125 | 30 | 30 | 50 | 275 | 40 | 140 | 37 | 25 | 4 | 26 Nm |

| Mod. | Ø | CX | L | DL+ | XN+ | MS | E | EX | EP | Z | Torque force |

| R-41-32 | 32 | 10 | 12 | 22 | 142 | 16 | 45 | 14 | 10,5 | 4 | 5 Nm |

| R-41-40 | 40 | 12 | 15 | 25 | 160 | 19 | 52 | 16 | 12 | 4 | 5 Nm |

| R-41-50* | 50 | 12 | 15 | 27 | 170 | 21 | 62,5 | 16 | 12 | 4 | 10 Nm |

| R-50 | 50 | 16 | 16 | 27 | 170 | 21,5 | 65 | 21 | 15 | 4 | 10 Nm |

| R-41-63 | 63 | 16 | 20 | 32 | 190 | 24 | 75 | 21 | 15 | 4 | 10 Nm |

| R-41-80* | 80 | 16 | 24 | 36 | 210 | 28 | 92 | 21 | 15 | 4 | 15 Nm |

| R-80 | 80 | 20 | 22 | 36 | 210 | 28,5 | 95 | 25 | 18 | 4 | 15 Nm |

| R-41-100 | 100 | 20 | 25 | 41 | 230 | 30 | 115 | 25 | 18 | 4 | 15 Nm |

| R-41-125 | 125 | 30 | 30 | 50 | 275 | 40 | 140 | 37 | 25 | 4 | 20 Nm |

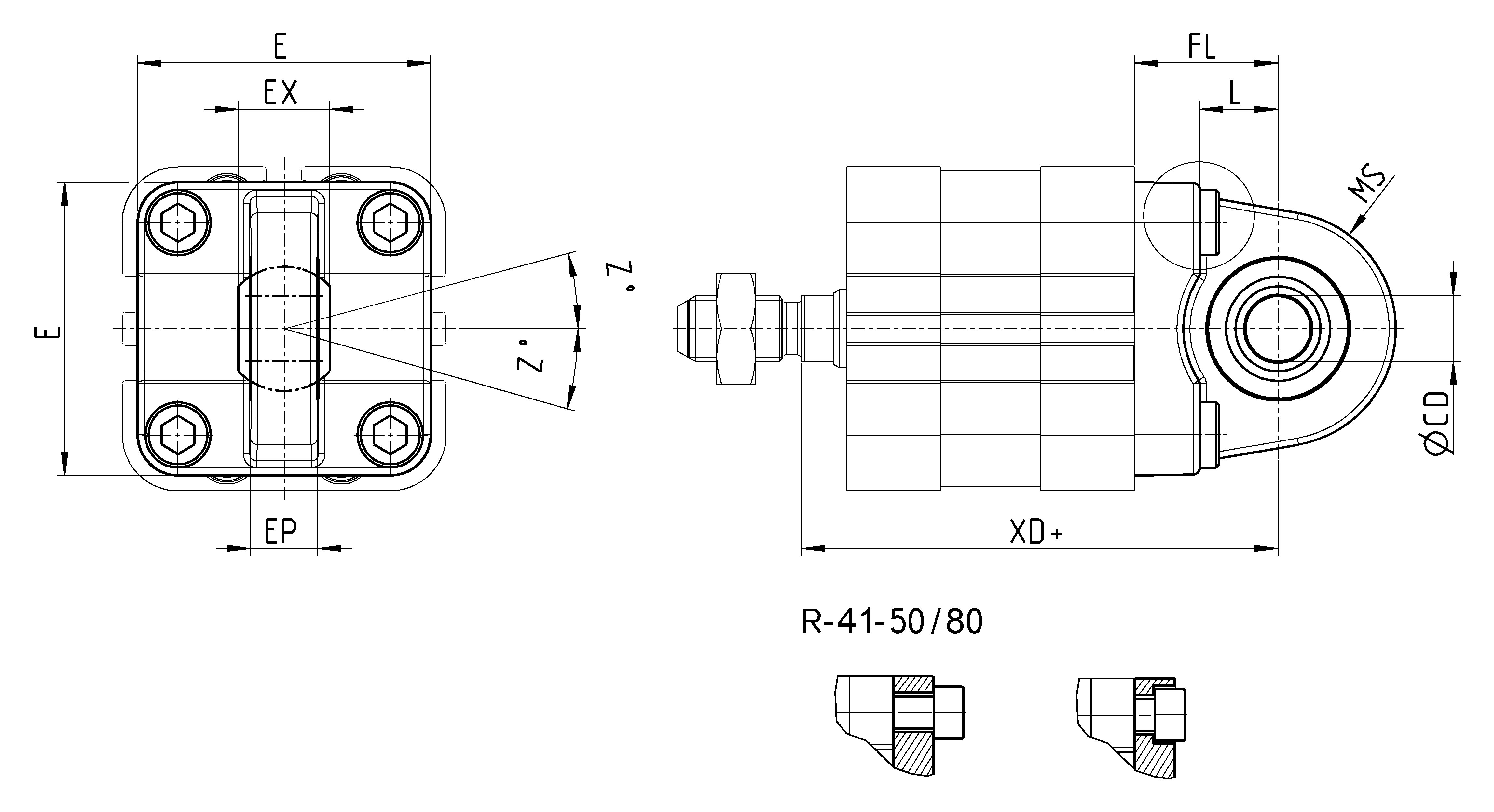

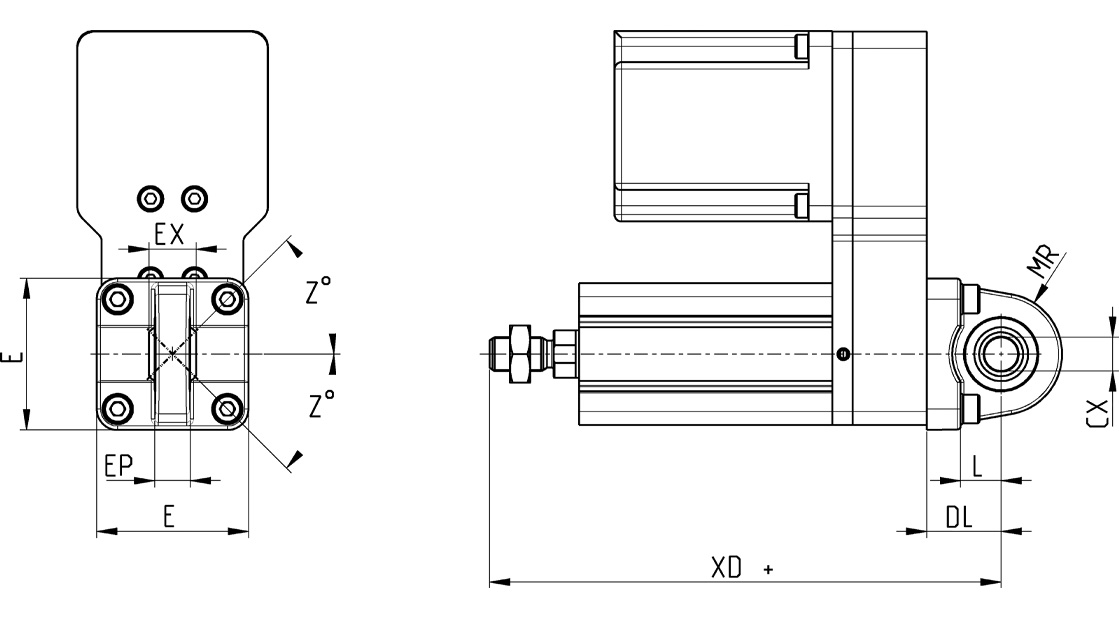

| Mod. | Ø | ØCD | E | EX | EP | L | FL | MS | XD+ | Z° |

| R-41-32 | 32 | 10 | 45 | 14 | 10,5 | 12 | 22 | 16 | 73 | 4 |

| R-41-40 | 40 | 12 | 52 | 16 | 12 | 15 | 25 | 19 | 77 | 4 |

| R-41-50* | 50 | 12 | 62,5 | 16 | 12 | 15 | 27 | 21 | 80 | 4 |

| R-50 | 50 | 16 | 65 | 21 | 15 | 16 | 27 | 21,5 | 80 | 4 |

| R-41-63 | 63 | 16 | 75 | 21 | 15 | 20 | 32 | 24 | 89 | 4 |

| R-41-80* | 80 | 16 | 92 | 21 | 15 | 24 | 36 | 28 | 99,5 | 4 |

| R-80 | 80 | 20 | 95 | 25 | 18 | 22 | 36 | 28,5 | 99,5 | 4 |

| R-41-100 | 100 | 20 | 115 | 25 | 18 | 27 | 41 | 30 | 117,5 | 4 |

| R-41-125 | 125 | 30 | 140 | 37 | 25 | 30 | 50 | 40 | 142 | 4 |

| Mod. | Ø | ØCD | E | EX | EP | L | FL | MS | XD+ | Z° |

| R-41-32 | 32 | 10 | 45 | 14 | 10,5 | 12 | 22 | 16 | 73 | 4 |

| R-41-40 | 40 | 12 | 52 | 16 | 12 | 15 | 25 | 19 | 77 | 4 |

| R-41-50* | 50 | 12 | 62,5 | 16 | 12 | 15 | 27 | 21 | 80 | 4 |

| R-50 | 50 | 16 | 65 | 21 | 15 | 16 | 27 | 21,5 | 80 | 4 |

| R-41-63 | 63 | 16 | 75 | 21 | 15 | 20 | 32 | 24 | 89 | 4 |

| R-41-80* | 80 | 16 | 92 | 21 | 15 | 24 | 36 | 28 | 99,5 | 4 |

| R-80 | 80 | 20 | 95 | 25 | 18 | 22 | 36 | 28,5 | 99,5 | 4 |

| R-41-100 | 100 | 20 | 115 | 25 | 18 | 27 | 41 | 30 | 117,5 | 4 |

| R-41-125 | 125 | 30 | 140 | 37 | 25 | 30 | 50 | 40 | 142 | 4 |

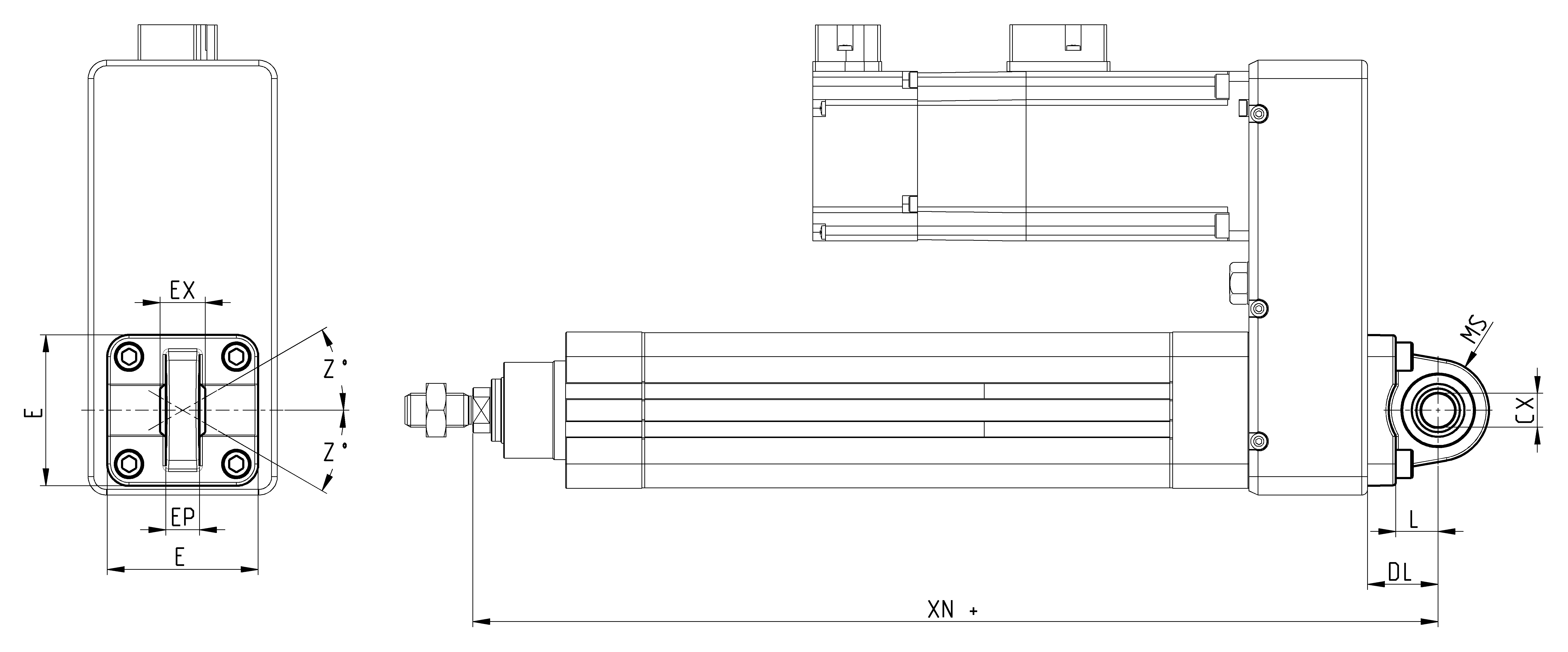

| Mod. | Size | CX | L | DL+ | XN+ | MS | E | EX | EP | Z |

| R-41-32 | 32 | 10 | 12 | 22 | 212 | 18 | 45 | 14 | 10.5 | 4° |

| R-41-40 | 40 | 12 | 15 | 25 | 246 | 18 | 53,5 | 16 | 12 | 4° |

| R-41-50 | 50 | 12* | 15 | 27 | 286 | 21 | 62,5 | 16* | 12* | 4° |

| R-41-63 | 63 | 16 | 20 | 32 | 324,5 | 23 | 75 | 21 | 15 | 4° |

| R-41-80 | 80 | 16* | 24 | 36 | 373 | 28 | 92 | 21* | 15* | 4° |

| R-41-100 | 100 | 20 | 29 | 41 | 401 | 30 | 115 | 25 | 18 | 4° |

| R-50 | 50 | 16 | 15 | 27 | 286 | 21 | 65 | 21 | 15 | 4° |

| R-80 | 80 | 20 | 20 | 36 | 373 | 28 | 95 | 25 | 18 | 4° |

Trunnion ball-joint Mod. R

Supplied with:

1x trunnion ball joint

4x screws*

*on end cap with END LOCK function, use screws Mod. KR (according to ISO 4026), supplied separately, see accessories “screws and locking screws Mod. KR”

** This trunnion doesn’t comply with the ISO 15552 standard Material: Aluminium

| Mod. | Ø | CX | L | DL+ | XN+ | XN+ | MS | E | EX | EP | Z | Screws for END LOCK* end-cap | Torque force |

| R-41-32 | 32 | 10 | 13 | 22 | 142 | 16 | 45 | 14 | 10.5 | 4 | M6 x 25 (KR-EL-01) | 5 Nm | |

| R-41-40 | 40 | 12 | 16 | 25 | 160 | 19 | 52 | 16 | 12 | 4 | M6 x 30 (KR-EL-02) | 5 Nm | |

| R-41-50** | 50 | 12 | 15 | 27 | 170 | 21 | 62.5 | 16 | 12 | 4 | M8 x 30 (KR-EL-05) | 10 Nm | |

| R-41-63 | 63 | 16 | 21 | 32 | 190 | 24 | 75 | 21 | 15 | 4 | M8 x 25 (KR-EL-04) | 10 Nm | |

| R-41-80** | 80 | 16 | 24 | 36 | 210 | 28 | 92 | 21 | 15 | 4 | M10 x 35 (KR-EL-08) | 15 Nm | |

| R-41-100 | 100 | 20 | 27 | 41 | 230 | 30 | 115 | 25 | 18 | 4 | M10 x 35 (KR-EL-08) | 15 Nm | |

| R-41-125 | 125 | 30 | 30 | 50 | 275 | 40 | 140 | 37 | 25 | 4 | - | 20 Nm | |

| R-50 | 50 | 16 | 16 | 27 | 170 | 21.5 | 65 | 21 | 15 | 4 | M8 x 25 (KR-EL-04) | 10 Nm | |

| R-80 | 80 | 20 | 22 | 36 | 210 | 28.5 | 95 | 25 | 18 | 4 | M10 x 30 (KR-EL-07) | 15 Nm |

Italy

Italy

.jpg)

.jpg)

.jpg)