Rodless cylinders

Series 52

Double-acting, magnetic, cushioned

Ø 25, 32, 40, 50, 63 mm

Ø 25, 32, 40, 50, 63 mm

Series 52 rodless cylinders are available in 5 diameters (25, 32, 40, 50 and 63 mm) and comes in three main versions: Basic (M), with Slide bearing (G) and with Roller bearings (R). Furthermore these three main versions are each available with either standard- or short carriage to cover a wider range of applications.

A permanent magnet is assembled on the piston allowing the position to be detected by means of proximity switches positioned in grooves located on 3 sides on the cylinder profile. The cylinder is equipped with an end stroke cushioning which can be regulated by means of a screw located on each end cover of the cylinder. These cylinders are also available in versions with air supply from one side (end cover) only if needed.

A permanent magnet is assembled on the piston allowing the position to be detected by means of proximity switches positioned in grooves located on 3 sides on the cylinder profile. The cylinder is equipped with an end stroke cushioning which can be regulated by means of a screw located on each end cover of the cylinder. These cylinders are also available in versions with air supply from one side (end cover) only if needed.

1-12/12 results

Series

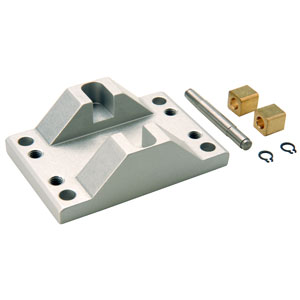

Accessories

Cylinder series 52 - 52G2C25A2560

Cylinder series 52 - 52G2C25A2680

Cylinder series 52 - 52G2C25A3065

Cylinder series 52 - 52G2C25A3265

Cylinder series 52 - 52G2C25A6000

Cylinder series 52 - 52G2C32A0050

Cylinder series 52 - 52G2C32A0100

Cylinder series 52 - 52G2C32A0150

Cylinder series 52 - 52G2C32A0200

Бесштоковый пневмоцилиндр - 52G2C32A0250

Cylinder series 52 - 52G2C32A0300

Cylinder series 52 - 52G2C32A0350

there are no salable codes online

Look in the "Accessory" tab for the Configurator

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| Models | Standard, with slide bearings, with roller bearings, air supply from one or both sides, with standard or short carriage. For sizes 50 - 63 roller bearings version is not available. |

| Materials | AL (anodized), plastic, hardened steel, seals: NBR, PU |

| Operating temperature | -10°C ÷ +70°C |

| Operating pressure | 1 ÷ 8 bar 1,5 ÷ 8 bar (Ø25 for "R" version) |

| Speed | 10 ÷ 1000 mm/sec (without load) |

| Fluid | filtered air, without lubrication. If lubricated air is used, it is recommended to use ISO VG32 oil. Once applied the lubrication should never be interrupted. If speeds exceed 1 m/s lubricated air is recommended. |

| Bore size | Ø25 Ø32 Ø40 Ø50 Ø63 |

| Cushioning length (mm) | 14 mm - Ø25 20 mm - Ø32 25 mm - Ø40 22 mm - Ø50 32 mm - Ø63 |

| Strokes with standard carriage (version "P") | max 6000 mm - Ø25 max 5950 mm - Ø32 max 5900 mm - Ø40, Ø50 max 5880 mm - Ø63 |

| Strokes with short carriage (version "C") | max 6000 mm |

| Stroke tolerance | strokes ≤ 1000 mm = 0 / +0,6 mm strokes > 1000 mm = 0 / +3 mm |

| Connection | G1/8 (Ø 25; 32) G1/4 (Ø 40) G3/8 (Ø 50; 63) |

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

CODING EXAMPLE

| 52 | M | 2 | P | 40 | A | 0500 |

| 52 | SERIES | |

| M |

VERSION M = standard G = with slide bearing R = with roller bearing (only Ø 25 - 32 - 40) |

|

| 2 |

OPERATION 2 = double-acting, cushioned, with air supply from both sides 8 = double-acting, cushioned, with air supply from one side only |

PNEUMATIC SYMBOLS CDSS (see the following pages) CDSS (see the following pages) |

| P |

MATERIALS P = anodized AL profile tube, NBR and PU seals, standard carriage C = anodized AL profile, NBR and PU seals, short carriage |

|

| 40 |

BORE 25 = 25 mm 32 = 32 mm 40 = 40 mm 50 = 50 mm 63 = 63 mm |

|

| A |

TYPE OF MOUNTING A = standard |

|

| 0500 |

STROKE (see table) |

1-8/8 results

Latvia

Latvia

Download catalogue

Download catalogue