Silencers in 316L stainless steel

Silencers

Silencers are indispensable elements for eliminating or reducing the characteristic noise of compressed air during discharge into the atmosphere. They should always be placed on the outlets of 3/2-, 5/2- or 5/3-way valves. When carrying out maintenance, silencers should be degreased using white spirit or paraffin and compressed air blown through them in the opposite direction to the direction of operation.

Flow rate: is measured at an inlet pressure of 6 bar with exhaust in the atmosphere. Noise level: is measured through a test using a phonometer. Placing the phonometer one meter away from the application and at the same height for ten seconds, gives an average reading of the noise generated.

Flow rate: is measured at an inlet pressure of 6 bar with exhaust in the atmosphere. Noise level: is measured through a test using a phonometer. Placing the phonometer one meter away from the application and at the same height for ten seconds, gives an average reading of the noise generated.

Series

Sst silencer - X2901 1

Sst silencer - X2901 1/2

Sst silencer - X2901 1/2PT

Sst silencer - X2901 1/4

Sst silencer - X2901 1/4PT

Stainless steel silencer - X2901 1/8

Sst silencer - X2901 1/8PT

Sst silencer - X2901 1PT

Sst silencer - X2901 3/4

Sst silencer - X2901 3/4PT

Stainless steel silencer - X2901 3/8

Sst silencer - X2901 3/8PT

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

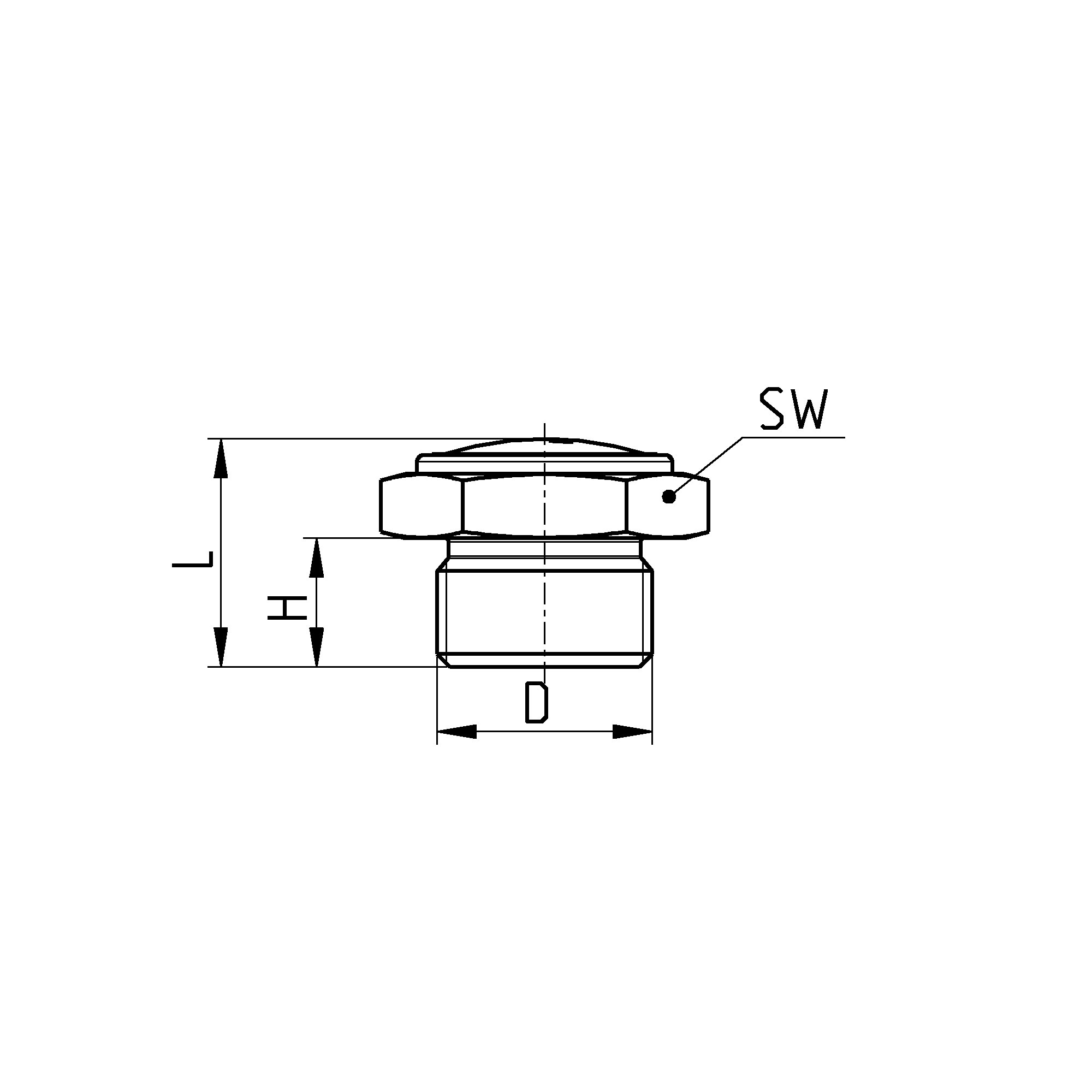

| Construction | body with male thread |

| Materials | 316L stainless steel |

| Thread | G1/8, G1/4, G3/8, G1/2, G3/4, G1 1/8NPT , 1/4NPT , 3/8NPT , 1/2NPT , 3/4NPT , 1NPT |

| Mod. | D | H | L | SW | Max operating pressure (bar) | Flow rate (NI/min) | Noise db (A) |

| X2901 1/8 | G1/8 | 8 | 15 | 14 | 10 | 700 | 76 |

| X2901 1/4 | G1/4 | 8 | 14 | 17 | 10 | 1000 | 78 |

| X2901 3/8 | G3/8 | 10 | 18 | 22 | 10 | 1500 | 76 |

| X2901 1/2 | G1/2 | 12 | 22 | 27 | 10 | 3400 | 86 |

| X2901 3/4 | G3/4 | 15 | 27 | 32 | 6 | 4100 | 87 |

| X2901 1 | G1 | 18 | 34 | 41 | 6 | 7600 | 88 |

| X2901 1/8PT | 1/8 NPT | 7 | 14 | 14 | 10 | 700 | 76 |

| X2901 1/4PT | 1/4 NPT | 11 | 17 | 17 | 10 | 1000 | 78 |

| X2901 3/8PT | 3/8 NPT | 11 | 19 | 22 | 10 | 1500 | 76 |

| X2901 1/2PT | 1/2 NPT | 15 | 25 | 27 | 10 | 3400 | 86 |

| X2901 3/4PT | 3/4 NPT | 16 | 28 | 32 | 6 | 4100 | 87 |

| X2901 1PT | 1 NPT | 19 | 35 | 41 | 6 | 7600 | 88 |

Latvia

Latvia

Download catalogue

Download catalogue