Cylinders ISO 15552

Series 63

Single and double-acting, magnetic, cushioned

Ø 32, 40, 50, 63, 80, 100, 125 mm

Ø 32, 40, 50, 63, 80, 100, 125 mm

The Series 63 pneumatic cylinders have been developed to guarantee high performance and versatility.

Thanks to a new system of adjustable pneumatic cushioning, the cylinders can always guarantee the best regulation whilst significantly reducing noise caused by the impact of the piston on the end block.

Besides the standard version, which can be used in many sectors, specific solutions have been developed for applications such as food processing, agriculture, in tensioning, dosing systems and dancer arms for winding applications. There are also versions for demanding application environments, capable of withstanding extreme temperatures, corrosive atmospheres etc.

Thanks to a new system of adjustable pneumatic cushioning, the cylinders can always guarantee the best regulation whilst significantly reducing noise caused by the impact of the piston on the end block.

Besides the standard version, which can be used in many sectors, specific solutions have been developed for applications such as food processing, agriculture, in tensioning, dosing systems and dancer arms for winding applications. There are also versions for demanding application environments, capable of withstanding extreme temperatures, corrosive atmospheres etc.

1-16/16 results

Series

Accessories

Cylinder s.63 profile - 63MP2C032A0010

Cylinder ser. 63 profile - 63MP2C032A0025

Cylinder s.63 profile - 63MP2C032A0040

Cylinder ser. 63 profile - 63MP2C032A0050

Cylinder s.63 profile - 63MP2C032A0075

Cylinder s.63 profile - 63MP2C032A0080

Cylinder ser. 63 profile - 63MP2C032A0100

Cylinder ser. 63 profile - 63MP2C032A0125

Cylinder s.63 profile - 63MP2C032A0150

Cylinder s.63 profile - 63MP2C032A0160

Cylinder s.63 profile - 63MP2C032A0200

Cylinder ser. 63 profile - 63MP2C032A0250

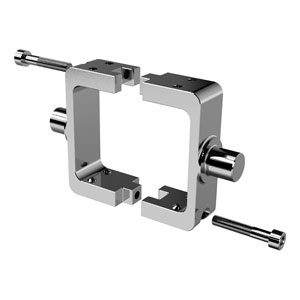

Accessory kit movement _ - DC-63-100

Accessory kit movement _ - DC-63-125

Accessory kit movement _ - DC-63-32

Accessory kit movement _ - DC-63-40

Accessory kit movement _ - DC-63-50

Accessory kit movement _ - DC-63-63

Accessory kit movement _ - DC-63-80

Foot mount - B-41-100

Foot mount - B-41-125

Foot mount - B-41-32

Foot mount - B-41-40

Foot mount - B-41-50

Foot mount - B-41-63

Foot mount - B-41-80

Front/rear flange - D-E-31-32

Front/rear flange - D-E-41-100

Front/rear flange - D-E-41-125

Front/rear flange - D-E-41-40

Front/rear flange - D-E-41-50

Front/rear flange - D-E-41-63

Front/rear flange - D-E-41-80

Front/rear trunnion (female) - C-H-41-100

Front/rear trunnion (female) - C-H-41-125

Rear trunnion (female) - C-H-41-63

Front/rear trunnion (female) - C-H-41-80

Rear trunnion (male) - L-41-100

Rear trunnion (male) - L-41-125

Rear trunnion (male) - L-41-32

Rear trunnion (male) - L-41-40

Rear trunnion (male) - L-41-50

Rear trunnion (male) - L-41-63

Rear trunnion (male) - L-41-80

Center trunnion - FN-100

Center trunnion - FN-125

Rear trunnion (ball joint) - R-41-100

Rear trunnion - R-41-125

Kit actuator - F-63-100

Kit actuator - F-63-125

Kit actuator - F-63-32

Kit actuator - F-63-40

Kit actuator - F-63-50

Kit actuator - F-63-63

Kit actuator - F-63-80

Counter bracket for cntr trn - BF-100-125

Mounting plate kit - PCV-62-K3

Mounting plate kit - PCV-62-K4

Mounting plate kit - PCV-62-K8

Mounting plate kit - PCV-62-KEN

Clevis pin - S-50

Piston rod socket joint - GY-50-63

Piston rod socket joint - GY-80-100

Rod clevis - G-25-32

Rod clevis - G-40

Rod clevis - G-41-125

Rod clevis - G-50-63

Rod clevis - G-80-100

Rod end alignment coupler - GK-50-63

Rod end algnmnt cplr m20x1,5 - GK-80-100

Compensator joint m10x1,25 - GKF-25-32

Coupler m12x1,25 - GKF-40

Compensator joint m16x1,50 - GKF-50-63

Compensator joints m20x1,50 - GKF-80-100

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| Type of construction | profile (with screws) and round tube (with tie-rods) |

| Design | ISO 15552 |

| Operation | single and double-acting |

| Type of mounting | with front / rear flange, foot mounting, with front / rear / centre / swivel trunnion |

| Stroke min - max | 10 ÷ 2500 mm |

| Operating temperature | standard and low friction: 0°C ÷ 80°C (with dry air -20°C) high temperatures (version W): 0°C ÷ 150°C (with dry air -20°C) low temperatures (version Z): -40°C ÷ 60°C (with dry air -40°C) low temperatures (version Y): -50°C ÷ 60°C (with dry air -50°C) |

| Storage temperature | 0°C ÷ 80°C (with dry air -20°C) |

| Operating pressure | 1 ÷ 10 bar (standard, high and low temperatures) 0,1 ÷ 10 bar (low friction) |

| Speed | 10 ÷ 1000 mm/sec, no load (standard, high and low temperatures) 5 ÷ 1000 mm/sec, no load (low friction and uniform movement) |

| Fluid | filtered air in class 7.8.4, according to ISO 8573-1. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| Use with sensors | model CSH |

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

CODING EXAMPLE

* Only for low friction

| 63 | M | P | 2 | C | 050 | A | 0200 | W |

| 63 | SERIES | |

| M |

VERSION M = standard, magnetic V = uniform movement (no stick slip), magnetic L = low friction, magnetic |

|

| P |

CONSTRUCTION T = round tube P = profile |

|

| 2 |

OPERATION 1 = single-acting, front spring 2 = double-acting 6 = double-acting, through-rod 7 = single-acting, through-rod 9 = single-acting, rear spring |

PNEUMATIC SYMBOLS CS07/CS18 CD08 - CD09 - CD10 - CD11 CD13 CS11 CS14/CS17 |

| C |

CUSHIONING N = no cushioning (mechanical endstops) C = cushioning on both sides F = front cushioning R = rear cushioning |

PNEUMATIC SYMBOLS CD08 CD09/CD13 CD11 CD10 |

| 050 |

BORE 032 = 32 mm 040 = 40 mm 050 = 50 mm 063 = 63 mm |

080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A |

CONSTRUCTIVE TYPE A = standard with rod nut RL = cylinder with rod lock |

DC = back to back cylinder with DC accessory [X1/X2] TR = back to back cylinder for round tube [X1/X2] F = cylinder with centre trunnion |

| 0200 |

STROKE = standard N = tandem / = more positions X1/X2 [X1<X2] |

|

| W |

TEMPERATURE RANGE = standard (-20°/+80°) W = high temperatures (150°C) |

Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

|

RESISTANCE TO CORROSION = standard C1 = rod nut AISI 304 stainless steel, rod AISI 304 stainless steel C2 = end cap treated screws (profile) or AISI 303 tie-rods and AISI 420B tie-rods (round tube) |

C3 = C2 + AISI 316 rod nut, AISI 316 rod C4 = C1 + C2 C5 = C3 + end caps with triple protection |

|

|

ROD VARIATIONS = standard (male rod thread) F = female rod thread K = end caps with Kanigen treatment (only for corrosion resistance category C2, C3 and C4) L = without rod seal (rear air inlet only)* V = FKM rod seal R = NBR rod seal U = unlubricated operation |

H = hydrolytic environment A = use in food and other frequent washdown applications G = dry and dusty environments (with brass rod scraper and chrome-plated stainless steel AISI 420B rod) B = cylinder with NBR bellow rod protection (_ _ _) = extended rod _ _ _ mm |

|

|

OTHER P = cylinder with RAL 7035 polyurethane coating |

||

|

CERTIFICATIONS EX = ATEX |

1-16/31 results

Malaysia

Malaysia

Download catalogue

Download catalogue

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)