Series

Accessories

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

Center trunnion - FN-100

Center trunnion - FN-125

Center trunnion - FN-50

Center trunnion - FN-63

End cap trunnion ser. 63 - FN-80

Kit actuator - F-63-100

Kit actuator - F-63-125

Kit actuator - F-63-32

Kit actuator - F-63-50

Kit actuator - F-63-63

Kit actuator - F-63-80

Accessory kit movement _ - DC-63-100

Accessory kit movement _ - DC-63-125

Accessory kit movement _ - DC-63-32

Accessory kit movement _ - DC-63-50

Accessory kit movement _ - DC-63-63

Accessory kit movement _ - DC-63-80

Mounting plate kit - PCV-62-K3

Mounting plate kit - PCV-62-K4

Mounting plate kit - PCV-62-K8

Mounting plate kit - PCV-62-KEN

addtocart.popup.message.success

请求的数量已部分确认

产品 {0} 已在您的购物车中,数量为 {1} 。您可以从购物车页面更新数量

产品未激活

由于库存不足,无法将此产品添加到购物车

数量必须大于零

产品 {0} 允许的最小数量为 {1}

产品 {0} 允许的最大数量为 {1}

产品 {0} 的包装尺寸是 {1}

无法将代码 {0} 的产品添加到此购物车

出现错误,请稍后重试或联系客户支持

CODING EXAMPLE

* Only for low friction

| 63 | M | P | 2 | C | 050 | A | 0200 | W |

| 63 | 系列 | |

| M |

VERSION M = standard, magnetic V = uniform movement (no stick slip), magnetic L = low friction, magnetic |

|

| P |

CONSTRUCTION T = round tube P = profile |

|

| 2 |

OPERATION 1 = single-acting, front spring 2 = double-acting 6 = double-acting, through-rod 7 = single-acting, through-rod 9 = single-acting, rear spring |

PNEUMATIC SYMBOLS CS07/CS18 CD08 - CD09 - CD10 - CD11 CD13 CS11 CS14/CS17 |

| C |

CUSHIONING N = no cushioning (mechanical endstops) C = cushioning on both sides F = front cushioning R = rear cushioning |

PNEUMATIC SYMBOLS CD08 CD09/CD13 CD11 CD10 |

| 050 |

孔径 032 = 32 mm 040 = 40 mm 050 = 50 mm 063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A |

CONSTRUCTIVE TYPE A = standard with rod nut RL = cylinder with rod lock |

DC = back to back cylinder with DC accessory [X1/X2] TR = back to back cylinder for round tube [X1/X2] F = cylinder with centre trunnion |

| 0200 |

STROKE = standard N = tandem / = more positions X1/X2 [X1<X2] |

|

| W |

TEMPERATURE RANGE = standard (-20°/+80°) W = high temperatures (150°C) |

Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

|

RESISTANCE TO CORROSION = standard C1 = rod nut AISI 304 stainless steel, rod AISI 304 stainless steel C2 = end cap treated screws (profile) or AISI 303 tie-rods and AISI 420B tie-rods (round tube) |

C3 = C2 + AISI 316 rod nut, AISI 316 rod C4 = C1 + C2 C5 = C3 + end caps with triple protection |

|

|

ROD VARIATIONS = standard (male rod thread) F = female rod thread K = end caps with Kanigen treatment (only for corrosion resistance category C2, C3 and C4) L = without rod seal (rear air inlet only)* V = FKM rod seal R = NBR rod seal U = unlubricated operation |

H = hydrolytic environment A = use in food and other frequent washdown applications G = dry and dusty environments (with brass rod scraper and chrome-plated stainless steel AISI 420B rod) B = cylinder with NBR bellow rod protection (_ _ _) = extended rod _ _ _ mm |

|

|

OTHER P = cylinder with RAL 7035 polyurethane coating |

||

|

认证 EX = ATEX |

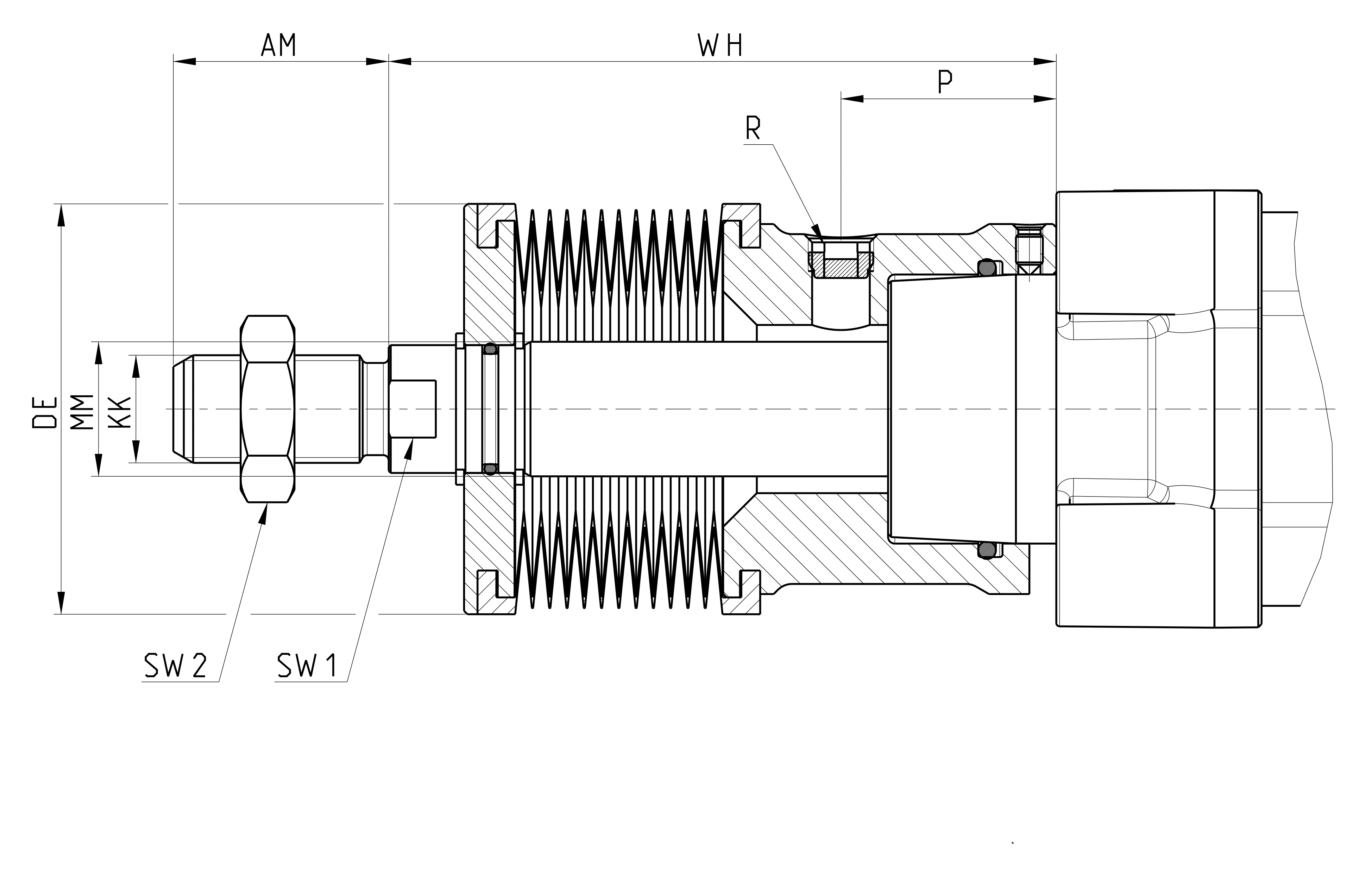

| 公称直径 ø | Stroke | WH | AM | KK | MM | P | R | DE | SW1 | SW2 |

| 32 | 0 ÷ 245 | 88 | 22 | M10x1,25 | 12 | 25 | G1/8 | 61 | 10 | 17 |

| 32 | 246 ÷ 490 | 132 | 22 | M10x1,25 | 12 | 25 | G1/8 | 61 | 10 | 17 |

| 40 | 0 ÷ 245 | 89 | 24 | M12x1,25 | 16 | 26 | G1/8 | 61 | 13 | 19 |

| 40 | 246 ÷ 490 | 133 | 24 | M12x1,25 | 16 | 26 | G1/8 | 61 | 13 | 19 |

| 50 | 0 ÷ 245 | 99 | 32 | M16x1,5 | 20 | 30 | G1/8 | 61 | 17 | 24 |

| 50 | 246 ÷ 490 | 143 | 32 | M16x1,5 | 20 | 30 | G1/8 | 61 | 17 | 24 |

| 63 | 0 ÷ 245 | 76 | 32 | M16x1,5 | 20 | 16.5 | G1/8 | 61 | 17 | 24 |

| 63 | 246 ÷ 490 | 120 | 32 | M16x1,5 | 20 | 16.5 | G1/8 | 61 | 17 | 24 |

| 80 | 0 ÷ 285 | 86 | 40 | M20x1,5 | 25 | 11.5 | G1/8 | 83 | 22 | 30 |

| 80 | 286 ÷ 570 | 139 | 40 | M20x1,5 | 25 | 11.5 | G1/8 | 83 | 22 | 30 |

| 100 | 0 ÷ 285 | 86 | 40 | M20x1,5 | 25 | 12 | G1/8 | 83 | 22 | 30 |

| 100 | 286 ÷ 570 | 139 | 40 | M20x1,5 | 25 | 12 | G1/8 | 83 | 22 | 30 |

| 125 | 0 ÷ 285 | 108 | 54 | M27x2 | 32 | 30 | G1/8 | 83 | 29 | 41 |

| 125 | 286 ÷ 570 | 161 | 54 | M27x2 | 32 | 30 | G1/8 | 83 | 29 | 41 |

马来西亚

马来西亚

样本下载

样本下载

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)