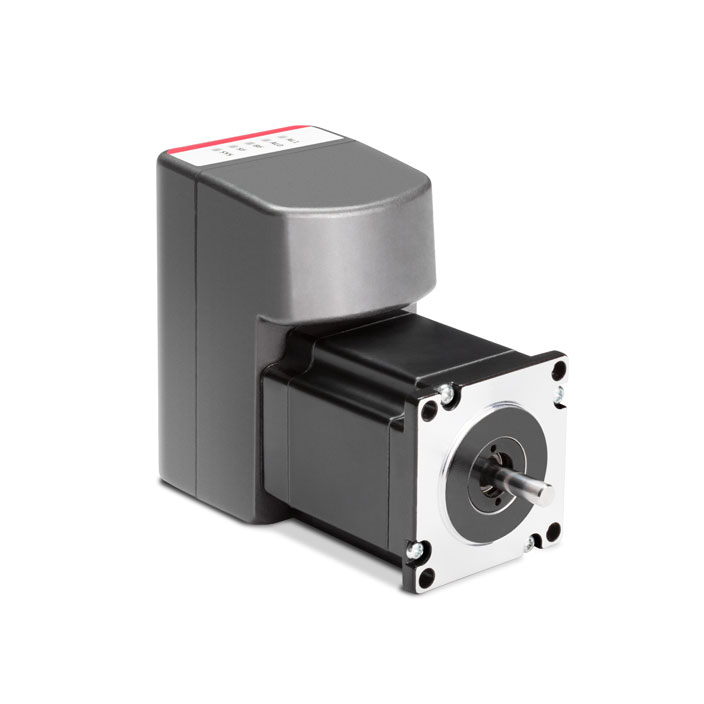

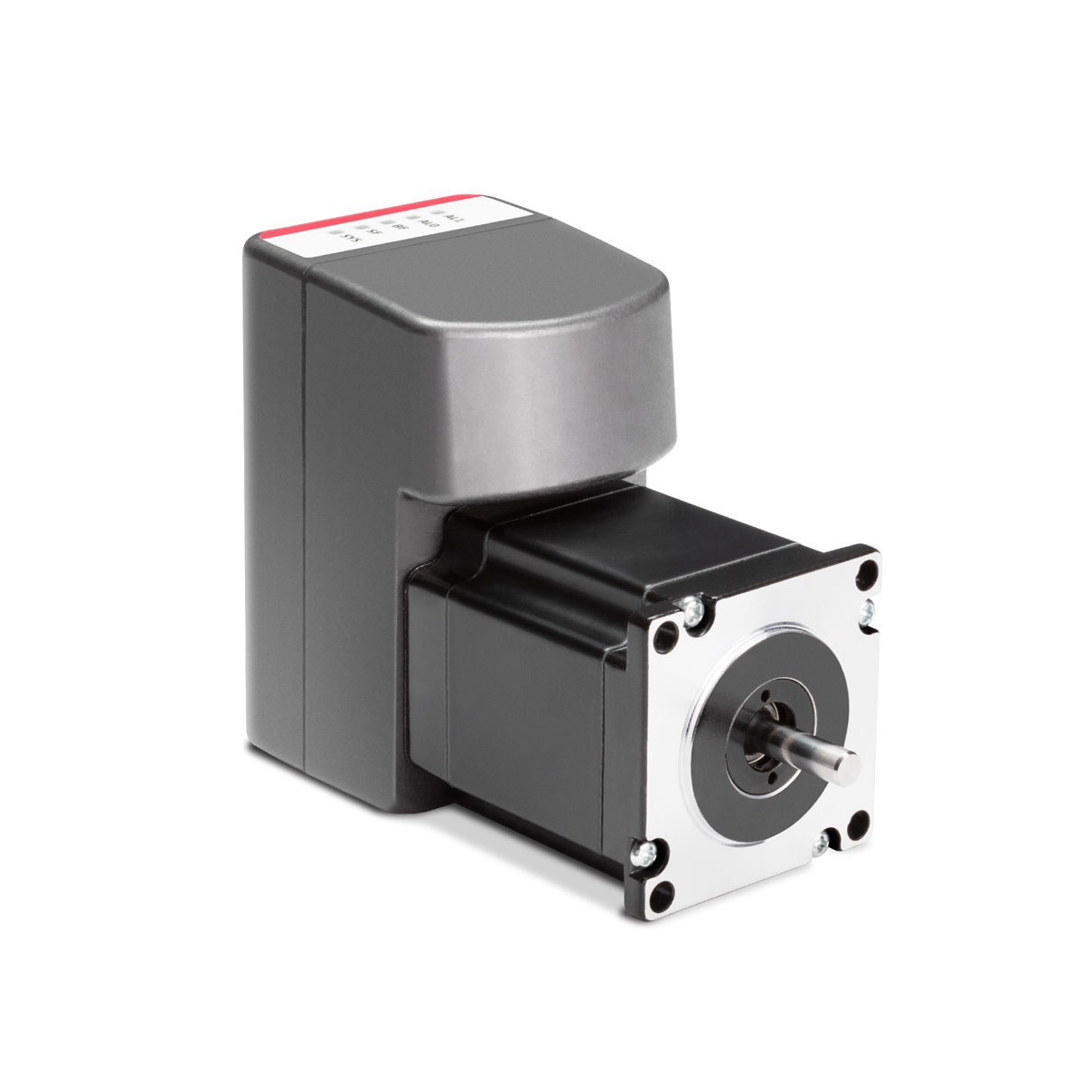

Integrated field-oriented control drive

Series DRVI

For stepper and brushless DC, Nema 23 and Nema 24 motors

The Series DRVI integrated motor drive is designed to control various types of motors, both stepper and brushless, using a closedloop control (FOC) algorithm. This algorithm, also known as vector control (FOC), offers better performance than traditional stepper motor control systems, which allows the stepper motor to operate over the entire speed range, ensuring fast acceleration and deceleration, assuring more accurate motion control with no loss of steps.

It is also more energy efficient than traditional control methods, as it uses precise rotor position feedback and controls the phase current, optimising motor operation. Its compact design and integration with the main communication protocols make the Series DRVI the ideal solution for various industrial applications that require accurate control and fast response to load variations.

It is also more energy efficient than traditional control methods, as it uses precise rotor position feedback and controls the phase current, optimising motor operation. Its compact design and integration with the main communication protocols make the Series DRVI the ideal solution for various industrial applications that require accurate control and fast response to load variations.

Series

Accessories

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

there are no salable codes online

Look in the "Accessory" tab for the Configurator

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| DRVI-23ST012-.. | DRVI-24ST022-.. | DRVI-24EC125-.. | |

| Motor type | Stepper | Stepper | Brushless DC |

| Flange size | NEMA 23 | NEMA 24 | NEMA 24 |

| Power supply | 24 - 48 VDC | 24 - 48 VDC | 24 - 48 VDC (nominal 48 V) |

| Logic supply | 24 VDC | ||

| GPIO (General-purpose input/output) | 2 digital inputs, for sensors (Homing and extra-stroke) 2 general digital inputs 1 general digital output |

||

| IP protection class | IP65, except motor shaft. (Caps must be fitted to unused connectors to ensure IP protection) |

||

| Control loop | Closed loop by field-oriented control (FOC) | ||

| Operation mode | Position Speed Torque |

||

| Communication protocol | Profinet CANopen EtherCAT EtherNet/IP |

||

| Additional function | STO (Safe Torque Off), SIL 2, Pld, not certified | ||

| Rated speed [rpm] | - | - | 3000 |

| Max speed [rpm] | 3000 | 3000 | 3000 |

| Rated torque [Nm] | - | - | 0,5 |

| Peak torque [Nm] | - | - | 1,5 |

| Torque at 0 rpm at 24VDC [Nm] | 1,2 | 2,2 | - |

| Rated power [W] | - | - | 125 |

| Rotor inertia [kg cm2] | 0,38 | 0,78 | 0,91 |

| Permissible radial load at the end of the shaft [N] | 50N | 60N | 60N |

| Weight [kg] | 1,1 | 1,6 | 1,1 |

| Weight with Brake [kg] | 1,85 | 2,35 | 1,85 |

| Encoder type | Absolute single turn | ||

| Recommended motor inertia ratio | <1:10 | ||

| Current Consumption [A] | 3,5 A | ||

| Current Consumption, logic [A] | <0,07A | ||

| Current Consumption with Brake [A] | 0,1A | ||

| General digital Input IN1, IN2 | isolated, compliant with IEC 61131-2 type 3 | ||

| Sensor digital input Homing, External | isolated input, differential, 24V | ||

| General digital output | Protected isolated input, maximum 400mA <0,2 | ||

| Maximum auxiliary current 24VDC [A] | <0,13 A | ||

| Protection | I2T, overvoltage, overcurrent, overtemperature | ||

| Operating temperature [°C] (no icing) | 0/+50°C | ||

| Humidity [%] (no condensing) | 15% - 90% | ||

| Installation max altitude [m] | 1000 | ||

| Vibration resistance | IEC 60068-2-6, IEC 60068-2-64 | ||

| Shock resistance | IEC 60068-2-27 | ||

| Brake resistance | Not present | ||

| BRAKE OPTION | |||

| Holding torque [Nm] | 1,5 Nm | ||

| Opening time [ms] | <=40 ms | ||

| Closing time [ms] | <=60 ms | ||

| Maximum single switching energy [J] | 115J | ||

| Service life, operating energy [J] | 23000J | ||

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

CODING EXAMPLE

| DRVI | - | 23 | ST | 012 | - | 0 | E | - | PN | SF |

| DRVI | SERIES |

| 23 |

MOTOR FLANGE 23 = Nema 23 24 = Nema 24 |

| ST |

MOTOR TYPE ST = stepper EC = brushless DC |

| 012 |

MOTOR TORQUE 012 = 1,2 Nm (Nema 23) 022 = 2,2 Nm (Nema 24) 125 = 125 W (Only for EC) |

| 0 |

MOTOR BRAKE 0 = without brake B = with brake |

| E |

MOTOR FEEDBACK E = absolute single turn encoder |

| PN |

COMMUNICATION PROTOCOL PN = Profinet CO = CanOpen EC = EtherCAT EI = EtherNet/IP |

| SF |

SAFETY FUNCTION = Standard SF = Safe torque off (not certified) |

1-16/19 results

United States

United States

Download catalogue

Download catalogue