Compact cylinders ISO 21287

Series 32

Single and double-acting, non-rotating, auto-cushioned

ø 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125 mm

ø 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125 mm

Series 32 cylinders, thanks to their compactness, are suitable for installation in confined spaces.

Being in compliance with the ISO 21287 Standard, the cylinders Series 32 can be used in conjunction with mountings/accessories suitable with ISO 15552 standard.

Being in compliance with the ISO 21287 Standard, the cylinders Series 32 can be used in conjunction with mountings/accessories suitable with ISO 15552 standard.

Series

Accessories

Compact cylinder ser. 32 - 32M2A080A300

Compact cylinder ser. 32 - 32M2A080A250

Compact cylinder ser. 32 - 32M2A080A150

Compact cylinder ser. 32 - 32M2A050A150

Compact cylinder ser. 32 - 32M2A032A150

Compact cylinder ser. 32 - 32F2A032A150

Compact cylinder ser. 32 - 32R2A050A100

Compact cylinder ser. 32 - 32M2A100A100

Compact cylinder ser. 32 - 32M2A063A100

Compact cylinder ser. 32 - 32M2A050A100

Compact cylinder ser. 32 - 32M2A040A100

Compact cylinder ser. 32 - 32M2A032A100

Foot mount - B-31-12-16

Foot mount - B-31-25

Foot mount - B-32-20

Foot mount - B-41-100

Foot mount - B-41-125

Foot mount - B-41-32

Foot mount - B-41-40

Foot mount - B-41-50

Foot mount - B-41-63

Foot mount - B-41-80

Front/rear flange - D-E-31-12-16

Front/rear flange - D-E-32-20

Front/rear flange - D-E-32-25

Front/rear flange - D-E-41-100

Front/rear flange - D-E-41-125

Front/rear flange - D-E-41-32

Front/rear flange - D-E-41-40

Front/rear flange - D-E-41-50

Front/rear flange - D-E-41-63

Front/rear flange - D-E-41-80

Rear trunnion (male) - L-31-12-16

Rear trunnion (male) - L-32-20

Rear trunnion (male) - L-32-25

Rear trunnion (male) - L-41-100

Rear trunnion (male) - L-41-125

Rear trunnion (male) - L-41-32

Rear trunnion (male) - L-41-40

Rear trunnion (male) - L-41-50

Rear trunnion (male) - L-41-63

Rear trunnion (male) - L-41-80

Rear trunnion (ball joint) - R-41-100

Rear trunnion - R-41-125

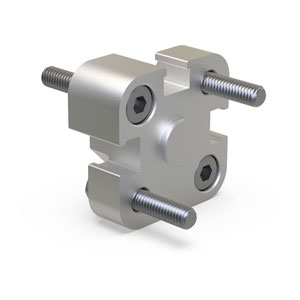

Rear trunnion bracket - I-20-25

Clevis pin - S-50

Rod clevis - G-12-16

Rod clevis - G-20

Rod clevis - G-25-32

Rod clevis - G-40

Rod clevis - G-50-63

Rod clevis - G-80-100

Swivel ball joint - GA-50-63

Compensator joint m10x1,25 - GKF-25-32

Coupler m12x1,25 - GKF-40

Compensator joint m16x1,50 - GKF-50-63

Centering ring for end caps - TR-32-100

Centering pin for end caps - TS-32-20

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| Construction | Compact profile |

| Operation | Single and double acting, magnetic |

| Design | ISO 21287 |

| Materials | Anodized AL body and end-blocks - rolled stainless steel AISI 303 rod Anodized AL piston - rod seal, end-block OR and piston seal in PU High temperatures: rod seal, OR end-block and piston in FKM (140°) |

| Mounting | With threaded holes on the end blocks Flange - feet - trunnion |

| Stroke min and max (*) | Ø12-16 = 5-200 mm Ø20-25 = 5-300 mm Ø32-40-50-63 = 5-400 mm Ø80-100-125 = 5-500 mm |

| Operating temperature | 0°C ÷ 80°C (with dry air -20°C) |

| Operating pressure | 1 ÷ 10 bar (double-acting) 2 ÷ 10 bar (single-acting) |

| Fluid | Clean air without lubrication. If lubricated air is used it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| Operation speed | 10 ÷ 700mm/sec. (without load) |

(*) the minimum stroke for the use of the sensors is 10 mm.

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

Coding example

| 32 | M | 2 | A | 032 | A | 050 |

| 32 | SERIES | |

| M |

VERSION M = male rod thread, mounted with rod nut Mod. U F = female rod thread R = antirotation with flange (from Ø20 to Ø100; no single-acting) |

|

| 2 |

OPERATION 1 = single-acting, front spring 2 = double-acting 3 = double-acting, through-rod 4 = single-acting, rear spring |

PNEUMATIC SYMBOLS CS06 CD08 CD12 CS08 |

| A |

MATERIALS A = anodized aluminium body, end blocks and piston, PU seals (rod, end-blocks OR and piston) |

|

| 032 |

BORES 012 = 12 mm 016 = 16 mm 020 = 20 mm 025 = 25 mm 032 = 32 mm 040 = 40 mm |

050 = 50 mm 063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A |

CONSTRUCTION A = standard |

|

| 050 | STROKE (see the table) | |

|

VARIANTS = standard V = FKM rod seal W = high temperatures (up to 140°C) non-magnetic (only for version M and F) (_ _ _) = stem longer than _ _ _ mm |

1-16/27 results

Bosnia and Herzegovina

Bosnia and Herzegovina

Download catalogue

Download catalogue

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)