Angle seat valves

Series ASP

2/2-way - Normally Closed (NC) and Normally Open (NO)

2/2-way - Double Acting (DA)

2/2-way - Double Acting (DA)

The Series ASP angle seat valves are an efficient and cost-effective solution for fluid control. Their robustness is suitable for the most varied applications with inert gases and liquids, with steam or with fluids having solid particulates in suspension. Available with 3/8" to 2-1/2" threaded connections.

The operation is determined by the pneumatic drive of a single acting, guided piston actuator with spring return.

There are also models available with double acting actuators, without spring.

For liquid media we recommend the models with flow direction under the seat.

For gas or steam we recommend the models with flow direction above the seat.

The operation is determined by the pneumatic drive of a single acting, guided piston actuator with spring return.

There are also models available with double acting actuators, without spring.

For liquid media we recommend the models with flow direction under the seat.

For gas or steam we recommend the models with flow direction above the seat.

1-5/5 results

Series

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| TECHNICAL FEATURES | |

| Function | 2/2 NC - 2/2 NO - 2/2 Double Acting |

| Operation | Pneumatic, poppet type |

| Pneumatic connection | 3/8 … 2-1/2“ with BSP thread |

| Nominal diameter | DN10 … DN65 |

| Flow coefficient Kv (m³/h) | 2.6 … 65 |

| Operating pressure | 0 ÷ 6 … 20 bar |

| Operating temperature | -20 ÷ 130 °C |

| Fluid | Water, air, steam, inert liquids and gases (compatible with the materials in contact) |

| Viscosity | 600 cSt. max |

| Installation | In any position |

| MATERIALS IN CONTACT WITH THE MEDIUM | |

| Body | Brass |

| Seals | EPDM |

| Internal parts | 304 stainless steel |

| SPECIFICATIONS PNEUMATIC ACTUATOR | |

| Actuator dimensions | Ø50 - Ø63 - Ø80 - Ø100 mm |

| Actuator material | PA66 polyamide 30% GF |

| Piston material | Aluminium |

| Piston seal material | PUR |

| Piloting fluid | Air or inert gases |

| Piloting pressure | 10 bar max. |

| Actuator position | 360° rotatable |

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

Coding example

| AS | P | A | 1 | - | W | 015 | G1 | - | 050 | P | 2 |

| AS | SERIES |

| P |

TYPE OF ACTUATOR P = technopolymer actuator |

| A |

BODY MATERIAL A = brass |

| 1 |

NUMBER OF WAYS - FUNCTIONS 0 = 2/2-way NO 1 = 2/2-way NC 3 = 2/2-way DA (Double Acting) |

| W |

FLOW DIRECTION W = under the seat (liquids and gases, anti-water hammer) Y = above the seat (gases) |

| 015 |

NOMINAL DIAMETER 010 = DN 10 015 = DN 15 020 = DN 20 025 = DN 25 032 = DN 32 040 = DN 40 050 = DN 50 065 = DN 65 |

| G1 |

BODY CONNECTION G1 = BSP thread DIN 228-1 |

| 050 |

ACTUATOR DIMENSION 050 = Ø50 mm 063 = Ø63 mm 080 = Ø80 mm 100 = Ø100 mm |

| P |

ACTUATOR MATERIAL P = PA66 polyammide 30% GF |

| 2 |

SEALS 2 = for standard temperatures -20 ÷ 130 °C |

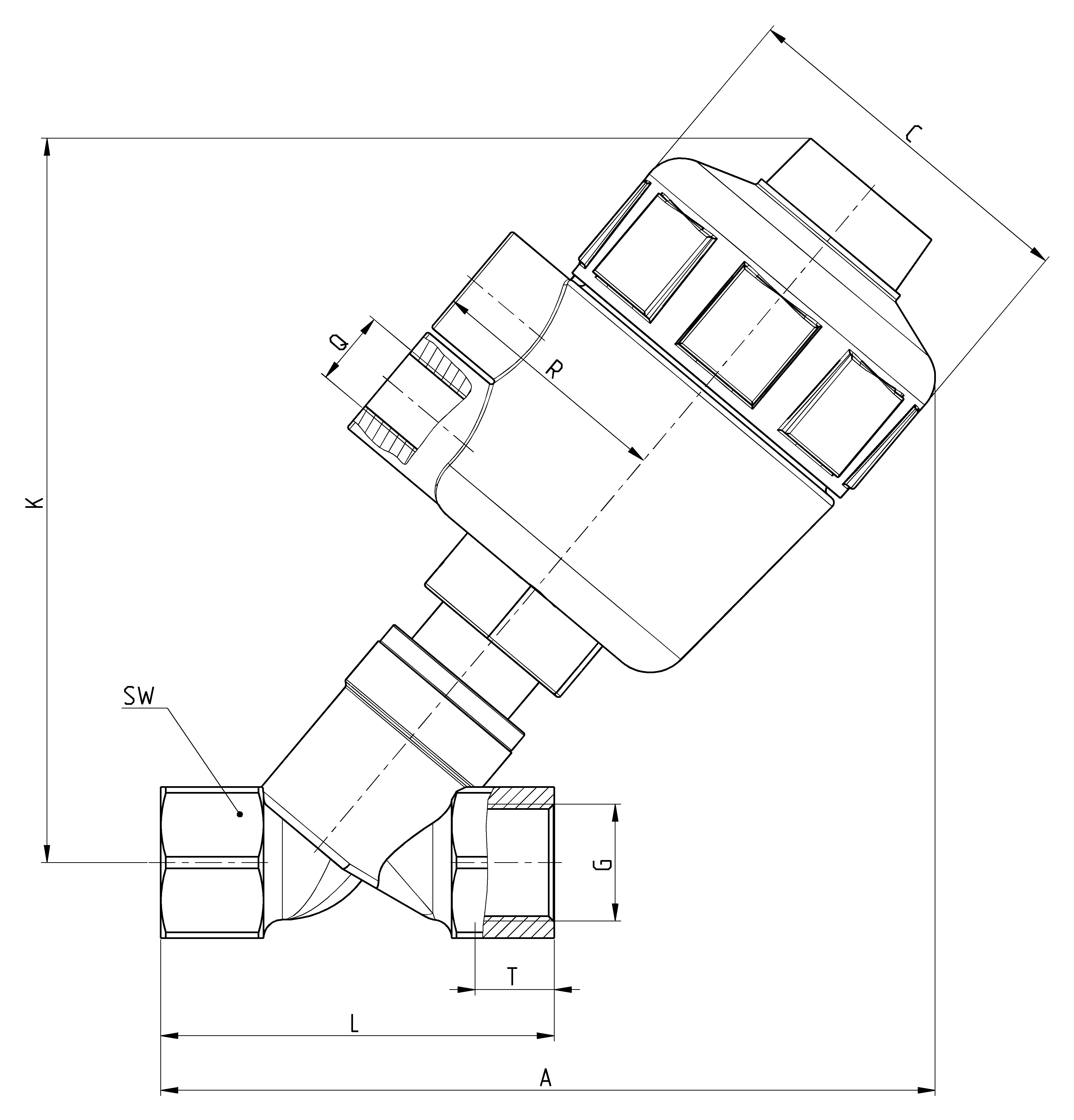

| DN | Actuator Ø (mm) | G | T | A | L | SW | C | R | K | Q | Kg |

| 10 | 50 | 3/8” | 12 | 125 | 49 | 21 | 66 | 45 | 115 | G1/4” | 0.8 |

| 15 | 50 | 1/2” | 13 | 130 | 55 | 26 | 66 | 45 | 115 | G1/4” | 0.9 |

| 15 | 63 | 1/2” | 13 | 160 | 55 | 26 | 83 | 52 | 150 | G1/4” | 1.2 |

| 20 | 50 | 3/4” | 13.5 | 135 | 65.5 | 31 | 66 | 45 | 115 | G1/4” | 1.0 |

| 20 | 63 | 3/4” | 13.5 | 165 | 65.5 | 31 | 83 | 52 | 150 | G1/4” | 1.3 |

| 25 | 50 | 1” | 16 | 140 | 76 | 38 | 66 | 45 | 115 | G1/4” | 1.3 |

| 25 | 63 | 1” | 16 | 170 | 76 | 38 | 83 | 52 | 150 | G1/4” | 1.6 |

| 32 | 63 | 1 1/4” | 18 | 180 | 96 | 48 | 83 | 52 | 180 | G1/4” | 2.1 |

| 32 | 80 | 1 1/4” | 18 | 210 | 96 | 48 | 103 | 60 | 210 | G1/4” | 1.6 |

| 40 | 80 | 1 1/2” | 18.5 | 220 | 101 | 54 | 103 | 60 | 220 | G1/4” | 2.6 |

| 40 | 100 | 1 1/2” | 18.5 | 230 | 101 | 54 | 130 | 73 | 230 | G1/4” | 4.5 |

| 50 | 80 | 2” | 19 | 230 | 120 | 67 | 103 | 60 | 230 | G1/4” | 2.9 |

| 50 | 100 | 2” | 19 | 240 | 120 | 67 | 130 | 73 | 240 | G1/4” | 5.3 |

| 65 | 100 | 2 1/2” | 23 | 250 | 149 | 85 | 130 | 73 | 240 | G1/4” | 6.5 |

Switzerland

Switzerland

Download catalogue

Download catalogue