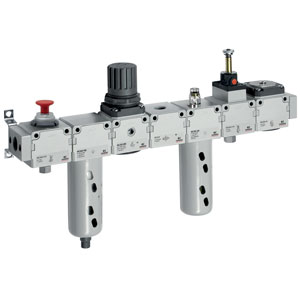

Assembled FRL

FRL units, or air preparation units, are essential in pneumatic automation as they combine filters, regulators, and lubricators to optimise the quality and control of compressed air. These units ensure that the air supplied to machinery is free from impurities, correctly pressurised, and lubricated, guaranteeing optimal performance and long equipment life.

Added to Your Shopping Cart

Maintenance and Efficiency

Maintaining FRL units is essential for preserving their efficiency. This includes regular replacement of filter elements and checking oil levels in lubricators. Proper maintenance ensures that air preparation units minimise energy consumption and maximise the life of pneumatic components.

Examples of Applications of Air Preparation Units

FRL units are used in various industrial sectors to optimise the performance and longevity of pneumatic tools. Here are several examples of their application:

- Industrial Automation: In robotics and automated production systems, FRL units are essential for ensuring clean air and constant pressure, improving reliability and precision of operations.

- Pharma and Life Sciences: FRL units ensure that the air used in production processes is clean and free of contaminants, a fundamental requirement for maintaining high hygiene standards.

- Automotive: FRL units guarantee effective and safe operation of pneumatic tools used in vehicle assembly and painting.

- Textiles Industry: Clean and regulated compressed air is crucial for the efficient operation of weaving machines and to avoid damage to delicate fibres.

Choosing the right FRL unit depends on various factors, including the required filtration level, flow and pressure specifications, and lubrication needs. It is important to select components suitable for the air volume and operating pressure of the system to ensure efficient performance and reduce energy consumption.

Importance of FRL Units

Their main function is to filter particles, regulate pressure, and provide adequate lubrication to compressed air. These units are designed to be easily integrated into existing pneumatic systems. They are available in various configurations and sizes to meet specific application needs, offering flexibility in system design and implementation.

Product Availability by Store Location

Hours

Estonia

Estonia