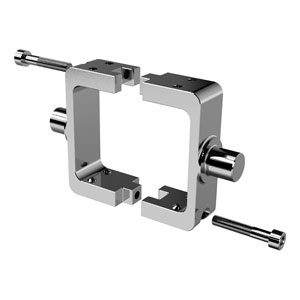

END LOCK cylinders

Series 63

Double-acting, magnetic, cushioned

ø 32, 40, 50, 63, 80, 100, 125 mm

ø 32, 40, 50, 63, 80, 100, 125 mm

END LOCK pneumatic cylinders are fitted with automatic mechanical end stroke locks which guarantee safe and secure holding of the cylinder rod in both the fully retracted and fully extended positions.

The locks activate and release automatically, without the need for external signals or commands and cylinder END LOCK Series 63 comply with ISO 15552.

The automatic mechanical lock therefore makes the END LOCK cylinders Series 63 highly suitable for use in sectors and for applications where it is essential to lock the cylinder’s position, both to avoid sliding during long stops and in situations with an absence of air, for example in transportation, printing & paper and the woodworking industry.

In addition, their capability to withstand external forces, that are much higher than the force exerted by the piston, makes the END LOCK cylinder the ideal solution for applications such as lifters, positioners and presses where a greater degree of safety is required compared to the more traditional rod locks combined with blocking valves.

The locks activate and release automatically, without the need for external signals or commands and cylinder END LOCK Series 63 comply with ISO 15552.

The automatic mechanical lock therefore makes the END LOCK cylinders Series 63 highly suitable for use in sectors and for applications where it is essential to lock the cylinder’s position, both to avoid sliding during long stops and in situations with an absence of air, for example in transportation, printing & paper and the woodworking industry.

In addition, their capability to withstand external forces, that are much higher than the force exerted by the piston, makes the END LOCK cylinder the ideal solution for applications such as lifters, positioners and presses where a greater degree of safety is required compared to the more traditional rod locks combined with blocking valves.

Series

Accessories

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

Foot mount - B-41-32

Foot mount - B-41-40

Foot mount - B-41-50

Foot mount - B-41-63

Foot mount - B-41-80

Front/rear flange - D-E-41-100

Front/rear flange - D-E-41-125

Front/rear flange - D-E-41-32

Front/rear flange - D-E-41-40

Front/rear flange - D-E-41-63

Front/rear trunnion (female) - C-H-41-100

Front/rear trunnion (female) - C-H-41-125

Rear trunnion (female) - C-H-41-63

Front/rear trunnion (female) - C-H-41-80

Rear trunnion (male) - L-41-100

Rear trunnion (male) - L-41-125

Rear trunnion (male) - L-41-32

Rear trunnion (male) - L-41-40

Rear trunnion (male) - L-41-50

Rear trunnion (male) - L-41-63

Rear trunnion (male) - L-41-80

Rear trunnion (ball joint) - R-41-100

Rear trunnion - R-41-125

Counter bracket for cntr trn - BF-100-125

Clevis pin - S-50

Rod clevis - G-25-32

Rod clevis - G-40

Rod clevis - G-41-125

Rod clevis - G-50-63

Rod clevis - G-80-100

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| Type of construction | profile (with screws) |

| Design | ISO 15552 |

| Operation | double-acting |

| Type of mounting | with front / rear flange, foot mounting, with front / rear / centre / swivel trunnion |

| Stroke min - max | 10 ÷ 2500 mm |

| Operating temperature | standard: 0°C ÷ 80°C (with dry air -20°C) high temperatures (version W): 0°C ÷ 150°C (with dry air -20°C) low temperatures (version Z): -40°C ÷ 60°C (with dry air -40°C) low temperatures (version Y): -50°C ÷ 60°C (with dry air -50°C) |

| Storage temperature | 0°C ÷ 80°C (with dry air -20°C) |

| Operating pressure | 2 ÷ 10 bar (standard, high and low temperatures) |

| Fluid | filtered air in class 7.8.4, according to ISO 8573-1. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| Use with sensors | model CSH |

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

Coding example

| 63 | M | P | 2 | C | 050 | A | 0400 | FL | W |

| 63 | SERIES | |

| M |

VERSION M = standard, magnetic |

|

| P |

CONSTRUCTION P = profile |

|

| 2 |

OPERATION 2 = double-acting |

|

| C |

CUSHIONING C = cushioning on both sides |

|

| 050 |

BORE 032 = 32 mm 040 = 40 mm 050 = 50 mm |

063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A |

CONSTRUCTION A = standard with rod nut DC = back to back cylinder with DC accessory [X1/X2] |

F = cylinder with centre trunnion |

| 0400 |

STROKE = standard |

|

| FL |

CONSTRUCTIVE TYPE FL = Front lock (extended rod lock) BL = Rear lock (retracted rod lock) DL = front & rear lock |

PNEUMATIC SYMBOLS CD34 CD35 CD36 |

| W |

TEMPERATURE RANGE* = standard (-20°/+80°) W = high temperatures (150°C) |

Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

|

CORROSION RESISTANCE* = standard C2 = treated end cap screws (profile) or AISI 303 tie-rod nuts and AISI 420B tie-rods (Ø 125) C3 = C2 + AISI 316 rod nut, AISI 316 rod |

C5 = C3 + end caps END LOCK with triple protection (only for constructive type FL and BL) |

|

|

TYPE OF MANUAL UNLOCKING = manual with M3 screw (not supplied) T = manual with unhooking pin and protective cover |

||

|

ROD VARIATIONS = standard (male rod thread) K = end caps without END LOCK with Kanigen treatment (only for lock type FL and BL, only for corrosion resistance category C2 and C3) V = FKM rod seal R = NBR rod seal |

G = dusty and dirty environments (with metal scraper and chrome-plated AISI 420B rod) B = cylinder with NBR bellow rod protection (___) = extended rod___ mm |

|

|

CERTIFICATIONS EX = ATEX |

1-16/21 results

Estonia

Estonia

Download catalogue

Download catalogue

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)