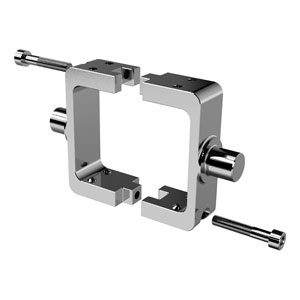

END LOCK cylinders

系列63

Double-acting, magnetic, cushioned

ø 32, 40, 50, 63, 80, 100, 125 mm

ø 32, 40, 50, 63, 80, 100, 125 mm

END LOCK pneumatic cylinders are fitted with automatic mechanical end stroke locks which guarantee safe and secure holding of the cylinder rod in both the fully retracted and fully extended positions.

The locks activate and release automatically, without the need for external signals or commands and cylinder END LOCK Series 63 comply with ISO 15552.

The automatic mechanical lock therefore makes the END LOCK cylinders Series 63 highly suitable for use in sectors and for applications where it is essential to lock the cylinder’s position, both to avoid sliding during long stops and in situations with an absence of air, for example in transportation, printing & paper and the woodworking industry.

In addition, their capability to withstand external forces, that are much higher than the force exerted by the piston, makes the END LOCK cylinder the ideal solution for applications such as lifters, positioners and presses where a greater degree of safety is required compared to the more traditional rod locks combined with blocking valves.

The locks activate and release automatically, without the need for external signals or commands and cylinder END LOCK Series 63 comply with ISO 15552.

The automatic mechanical lock therefore makes the END LOCK cylinders Series 63 highly suitable for use in sectors and for applications where it is essential to lock the cylinder’s position, both to avoid sliding during long stops and in situations with an absence of air, for example in transportation, printing & paper and the woodworking industry.

In addition, their capability to withstand external forces, that are much higher than the force exerted by the piston, makes the END LOCK cylinder the ideal solution for applications such as lifters, positioners and presses where a greater degree of safety is required compared to the more traditional rod locks combined with blocking valves.

Series

Accessories

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

Accessory kit movement _ - DC-63-100

Accessory kit movement _ - DC-63-125

Accessory kit movement _ - DC-63-32

Accessory kit movement _ - DC-63-50

Accessory kit movement _ - DC-63-63

Accessory kit movement _ - DC-63-80

Center trunnion - FN-100

Center trunnion - FN-125

Center trunnion - FN-50

Center trunnion - FN-63

End cap trunnion ser. 63 - FN-80

Kit actuator - F-63-100

Kit actuator - F-63-125

Kit actuator - F-63-32

Kit actuator - F-63-50

Kit actuator - F-63-63

Kit actuator - F-63-80

addtocart.popup.message.success

请求的数量已部分确认

产品 {0} 已在您的购物车中,数量为 {1} 。您可以从购物车页面更新数量

产品未激活

由于库存不足,无法将此产品添加到购物车

数量必须大于零

产品 {0} 允许的最小数量为 {1}

产品 {0} 允许的最大数量为 {1}

产品 {0} 的包装尺寸是 {1}

无法将代码 {0} 的产品添加到此购物车

出现错误,请稍后重试或联系客户支持

| 结构形式 | profile (with screws) and round tube (with tie-rods) |

| 设计 | ISO 15552 |

| 与介质接触的材料 | single and double-acting |

| 安装方式 | with front / rear flange, foot mounting, with front / rear / centre / swivel trunnion |

| 行程 | 10 ÷ 2500 mm |

| 工作温度 | standard and low friction: 0°C ÷ 80°C (with dry air -20°C) high temperatures (version W): 0°C ÷ 150°C (with dry air -20°C) low temperatures (version Z): -40°C ÷ 60°C (with dry air -40°C) low temperatures (version Y): -50°C ÷ 60°C (with dry air -50°C) |

| 存储温度 | 0°C ÷ 80°C (with dry air -20°C) |

| 可按要求定制特殊类型的产品 | 1 ÷ 10 bar (standard, high and low temperatures) 0.1 ÷ 10 bar (low friction) |

| 介质 | filtered air in class 7.8.4, according to ISO 8573-1. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| 磁性接近开关 | model CSH |

CODING EXAMPLE

| 63 | M | P | 2 | C | 050 | A | 0400 | FL | W |

| 63 | SERIES | |

| M |

VERSION: M = standard, magnetic L = low friction, magnetic |

|

| P |

CONSTRUCTION: T = round tube P = profile |

|

| 2 |

OPERATION: 1 = single-acting, front spring 2 = double-acting 6 = double-acting, through-rod 7 = single-acting, through-rod 9 = single-acting, rear spring |

|

| C |

CUSHIONING: N = no cushioning C = cushioning on both sides F = front cushioning R = rear cushioning |

|

| 050 |

BORE: 032 = 32 mm 040 = 40 mm 050 = 50 mm 063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A | A |

F = cylinder with centre trunnion |

| 0400 |

STROKES: 10 ÷ 2500 mm |

|

| FL |

CONSTRUCTIVE TYPE: A = standard with rod nut RL = cylinder with rod lock F = cylinder with centre trunnion |

PNEUMATIC SYMBOLS CD34 CD35 CD36 |

| W |

TEMPERATURE RANGE: = standard W = high temperatures (150°C) Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

|

CORROSION RESISTANCE* = standard C2 = treated end cap screws (profile) or AISI 303 tie-rod nuts and AISI 420B tie-rods (Ø 125) C3 = C2 + AISI 316 rod nut, AISI 316 rod |

C5 = C3 + end caps END LOCK with triple protection (only for constructive type FL and BL) |

|

|

RESISTANCE TO CORROSION: = standard (see the table of materials on page 1/1.28.03) C1 = rod nut AISI 304 stainless steel, rod AISI 304 stainless steel (other materials: see the table of materials on page 1/1.28.03) |

||

|

ROD VARIATIONS: = standard ( _ _ _ ) = rod longer than _ _ _ mm L = without rod seal (rear supply only) * R = NBR rod seal V = FKM rod seal G = dry and dusty environments (with brass rod scraper and chrome-plated stainless steel AISI 420B rod) * The possibility to order the cylinder without piston rod seal, further reduces the friction force. |

G = dusty and dirty environments (with metal scraper and chrome-plated AISI 420B rod) B = cylinder with NBR bellow rod protection (___) = extended rod___ mm |

|

| Add EX to order the ATEX certified version. |

中国香港

中国香港

样本下载

样本下载

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)