Drives

Electric drives are devices used to control the speed, direction, and behaviour of electric motors in industrial applications. These systems are fundamental in industrial automation, where precise motion control is essential for optimising production processes and reducing energy consumption. Drives modulate the power supplied to motors based on real-time feedback on working conditions, allowing fine and dynamic control of motor performance. With advances in technology, drives have become more efficient, integrating advanced features and safety functions.

Added to Your Shopping Cart

Electric Drive

These devices are essential for the precise regulation of machine and industrial process performance, offering advanced capabilities in speed and position control. Electric drives can manage different types of motors, including asynchronous and synchronous ones, adapting to a wide range of industrial applications because of their flexibility and ability to interface with modern automation systems and communication protocols.

Stepper Drives and Servo Drives

Stepper drives allow precise step-by-step control of motors, ideal for applications requiring exact positioning without the need for external feedback. Whereas servo drives, use a feedback system to dynamically regulate position, speed, and torque, offering a more versatile solution suitable for applications requiring high performance and rapid response times.

Servo Drives and Stepper Drives

These devices are essential in automation for the precise control of electric motors. Servo drives, also known as servo amplifiers or controllers, regulate motor position, speed, and current based on signals received from a central control system. These devices are ideal for applications requiring high precision and dynamic response, such as positioning systems and pick-and-place applications. Stepper drives, on the other hand, control stepper motors that divide a full rotation into many small ‘steps’, allowing extremely precise and repeatable movements without the need for position feedback. This makes them suitable for applications where movement precision and consistency are critical, such as 3D printers and CNC machining centres.

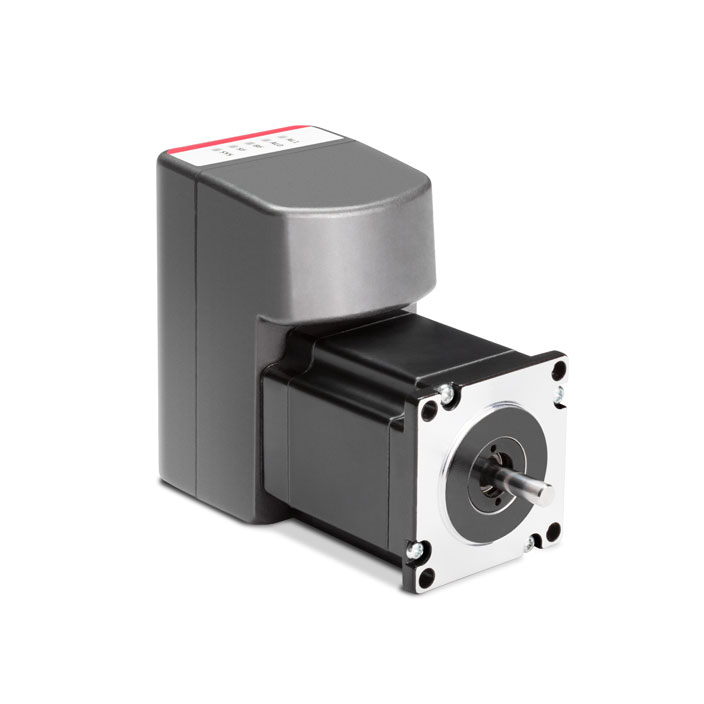

Integrated Drive

These devices combine the motor and drive into a single unit, reducing footprint and wiring complexity. Integrated drives optimise the efficiency and responsiveness of motion systems.

Industrial Drives

Industrial drives are crucial systems for automation, offering exceptional adaptability and high performance. These devices control and regulate the speed, torque, and position of electric motors, adapting to various applications because of their ability to interface with different types of motors and feedback systems. Their versatility makes them ideal for sectors requiring precision in motion control, such as packaging and robotics.

Motor Drives

Motor drives are designed to control and optimise the operation of electric motors. These systems allow precise regulation of motor speed, torque, and position, adapting to various application requirements due to their configurability. They can handle both DC and AC motors, including synchronous and asynchronous ones, making them versatile for use across many different industrial sectors.

Stepper and Brushless Drives

Stepper motors are known for their precise positioning capabilities achieved through step-by-step control which allows detailed and accurate movements and is ideal for applications requiring a fixed position when not powered. Alternatively, brushless motors offer smoother movement and higher speeds with greater energy efficiency compared to stepper motors.

Servo Drives

Also known as servo motor controllers, these are devices used to control the precision of servo motors in industrial and automation applications. They regulate the speed, position, and torque of the servo motor in response to command signals received from a control system, such as a PLC or industrial computer. Servo drives operate within a closed-loop control system, using real-time feedback from the motor to continuously adjust its performance. This allows for highly precise control of mechanical motion, essential in applications requiring complex and highly accurate movements.

Brushless Motor Drives

Brushless motor drives are designed to offer optimal speed and position control, combined with significant energy savings achieved through their high efficiency. These systems lack brushes, which greatly reduces maintenance and improves motor lifespan. Whereas integrated drives combine motors and controls into a single compact solution, simplifying installation and maximising performance by enabling optimal synergy between components.

Product Availability by Store Location

Hours

Indonesia

Indonesia