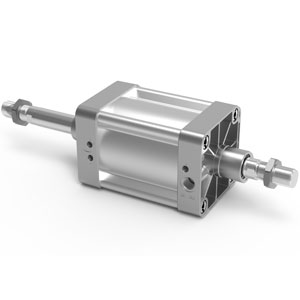

Cylinders aluminium profile

Series 41K

Double-acting, cushioned, magnetic

ø 160 - 200 mm

ø 160 - 200 mm

Series 41K cylinder comply with the ISO 15552 standard and can be assembled with the entire range of standard accessories.

The mounting brackets used on the end-blocks tube are designed in an extremely secure way, making use of cylinder tie-rods positioned internally and not visible on the assembled cylinder.

This cylinder series is normally equipped with adjustable endstroke cushioning by means of a screw positioned on the end-block.

The mounting brackets used on the end-blocks tube are designed in an extremely secure way, making use of cylinder tie-rods positioned internally and not visible on the assembled cylinder.

This cylinder series is normally equipped with adjustable endstroke cushioning by means of a screw positioned on the end-block.

Series

Accessories

there are no salable codes online

If you have entered Filters, try changing them or look in the "Configurator" tab

Foot mount - B-41-160

Foot mount - B-41-200

Front/rear flange - D-E-41-160

Front/rear flange - D-E-41-200

Front/rear trunnion (female) - C-H-41-160

Front/rear trunnion (female) - C-H-41-200

Rear trunnion (male) - L-41-160

Rear trunnion (male) - L-41-200

Center trunnion - F-41-160

Center trunnion - F-41-200

Inclined trunnion _ - ZS-200N

Counter bracket for cntr trn - BF-160-200

Rod clevis - G-160-200

Swivel ball joint - GA-160-200

Clevis pin (pivot pin) - S-160-200

Self-aligning rod m36x2 - GK-160-200

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

| Type of construction | profile (with tie-rods) |

| Operation | double-acting |

| Design | ISO 15552 |

| Materials | AL end blocks and piston - rolled AISI 420B stainless steel piston rod - zinc-plated steel piston rod nut - anodized AL-profile tube zinc-plated steel tie-rods and tie-rod nuts - NBR-PU rod - piston - cushion seals - brass rod scraper |

| Mounting | with front flange - rear flange - foot mounts - centre trunnion - front and rear trunnion |

| Strokes min - max | 10 ÷ 2500 mm |

| Operating temperature | 0°C ÷ 80°C (with dry air - 20°C) |

| Operating pressure | 1 ÷ 10 bar |

| Speed | 10 ÷ 500 mm/sec (without load) ATEX version Ø 160 - 200 10 ÷ 500 mm/sec |

| Fluid | filtered air, without lubrication. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted |

addtocart.popup.message.success

The requested quantity is partially confirmed

Product {0} is already in your cart with quantity {1}. You can update the quantity from cart page.

Product is not active

The product could not be added to the cart due to insufficient stock

Quantity must be greater than zero

Min allowed quantity for product {0} is {1}

Max allowed quantity for product {0} is {1}

Pack size for product {0} is {1}

It is not possible to add the product with code {0} to this cart

An error occurred, please try again later or contact customer support

CODING EXAMPLE

| 41 | K | 2 | P | 160 | A | 0200 |

| 41 | SERIES | |

| K |

VERSION K = standard magnetic |

|

| 2 |

OPERATION 2 = double-acting, front and rear cushions 3 = double-acting, no cushion 4 = double-acting, rear cushions 5 = double-acting, front cushion 6 = double-acting, through-rod, front and rear cushions 8 = double-acting, through-rod, no cushion |

PNEUMATIC SYMBOLS CD09 CD07 CD37 CD38 CD13 CD14 |

| P |

MATERIALS P = see the GENERAL DATA table on the previous page R = AISI 420B stainless steel tie-rods, AISI 303 stainless steel tie-rod nuts C = rolled AISI 303 stainless steel piston rod, AISI 304 stainless steel piston rod nut U = rolled stainless steel AISI 303 piston rod, AISI 304 stainless steel piston rod nut, stainless steel AISI 420B tie-rods, stainless steel AISI 303 tie-rod nuts, AISI 420B stainless steel tie-rods, AISI 303 stainless steel tie-rod nuts W = rolled AISI 304 stainless steel piston rod, AISI 304 stainless steel piston rod nut, AISI 420B stainless steel tie-rods, AISI 303 stainless steel tie-rod nuts |

|

| 160 |

BORE 160 = 160 mm - 200 = 200 mm |

|

| A |

TYPE OF DESIGN A = standard F = cylinder with centre trunnion |

|

| 0200 | STROKE (see the table) | |

|

= standard V = FKM rod seal W = all seals in FKM +130°C C = PU coated cylinder. Colour: Grey G = with brass rod scraper (chrome plated AISI 420B stainless steel rod, NBR rod seal) ( _ _ _ ) = extended piston rod _ _ _ mm Note: Version C is available on request. For further information, please contact our technical dept. |

||

|

CERTIFICATIONS EX = ATEX |

1-16/16 results

India

India

Download catalogue

Download catalogue

.jpg)

.jpg)

.jpg)