Gearboxes and Coupling

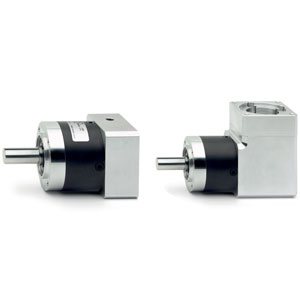

Planetary gearboxes are advanced motion transmission mechanisms that use a system of gears arranged concentrically around a central gear. They are valued for their ability to offer high reduction ratios in compact spaces, ensuring high precision and load capacity. These gearboxes are particularly effective in applications requiring reduced dimensions and high performance, such as automation systems and precision handling devices.

Added to Your Shopping Cart

Self-centering locking set

The self-centering locking set is a precision device designed to ensure the mounting between a shaft and a hub, ensuring concentricity and reducing mechanical play. This tool is particularly useful for assemblies requiring a high level of precision in motion transmission, offering a secure and stable connection between mechanical parts. Because of their design, self-centering locking sets facilitate easy installation and automatic centering, allowing an even distribution of clamping forces, and improving the overall system's transmission performance and durability.

Key Components for Motion Transmission

The construction of a planetary gearbox includes several key components: the sun gear, the planetary gears rotating around the sun, and the ring gear, which is an outer ring with internal teeth that mesh with the planetary gears. This configuration allows for even load distribution across the various gears, increasing the gearbox's lifespan and durability.

Additionally, planetary gearboxes are known for their operational efficiency and can handle high loads because of their robust construction. They are available in various configurations to suit a wide range of industrial applications, offering tailored solutions that meet specific motion control and handling needs.

Couplings for Electric Motors

Couplings for electric motors are essential mechanical components that connect a motor shaft with another device's shaft, allowing the transmission of rotational movement. These couplings compensate for any misalignment between shafts and reduce loads transmitted back to the motor, thereby improving the overall system's durability and performance. Couplings for electric motors can be constructed from various materials and in different configurations, depending on the specific application requirements, such as the operating environment or the type of movement needed.

Product Availability by Store Location

Hours

United Kingdom

United Kingdom