Cylinders ISO 15552

Series 63

Single and double-acting, magnetic, cushioned

Versions: standard, low friction, high and low temperatures

Ø 32, 40, 50, 63, 80, 100, 125 mm

Versions: standard, low friction, high and low temperatures

Ø 32, 40, 50, 63, 80, 100, 125 mm

The new Series 63 pneumatic cylinders, which comply with the ISO 15552 standard, have been developed to guarantee high performance whilst also offering significant reductions in weight.

The new adjustable pneumatic and mechanical cushioning system ensures Series 63 also reduces the noise caused by the impact of the piston on the end block.

On one side of the profile, there are grooves for the positioning of proximity switches (Series CSH) for the detection of the piston's position. These grooves can be covered with the slot cover profile Mod. S-CST-500. A wide range of versions are available which makes these new cylinders suitable for use in many sectors and applications.

The new adjustable pneumatic and mechanical cushioning system ensures Series 63 also reduces the noise caused by the impact of the piston on the end block.

On one side of the profile, there are grooves for the positioning of proximity switches (Series CSH) for the detection of the piston's position. These grooves can be covered with the slot cover profile Mod. S-CST-500. A wide range of versions are available which makes these new cylinders suitable for use in many sectors and applications.

1-16/16 结果

Series

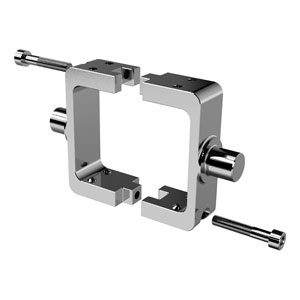

Accessories

Cylinder s.63 profile - 63MP2C032A0010

Cylinder ser. 63 profile - 63MP2C032A0025

Cylinder ser. 63 profile - 63MP2C040A0025

Cylinder s.63 profile - 63MP2C063A0025

Cylinder s.63 profile - 63MP2C080A0025

Cylinder s.63 profile - 63MP2C125A0025

Cylinder ser. 63 tube - 63MT2C032A0025

Cylinder s. 63 tube - 63MT2C050A0025

Cylinder ser. 63 tube - 63MT2C063A0025

Cylinder s.63 profile - 63MP2C040A0030

Accessory kit movement _ - DC-63-100

Accessory kit movement _ - DC-63-125

Accessory kit movement _ - DC-63-32

Accessory kit movement _ - DC-63-50

Accessory kit movement _ - DC-63-63

Accessory kit movement _ - DC-63-80

Center trunnion - FN-100

Center trunnion - FN-125

Center trunnion - FN-50

Center trunnion - FN-63

End cap trunnion ser. 63 - FN-80

Kit actuator - F-63-100

Kit actuator - F-63-125

Kit actuator - F-63-32

Kit actuator - F-63-50

Kit actuator - F-63-63

Kit actuator - F-63-80

Mounting plate kit - PCV-62-K3

Mounting plate kit - PCV-62-K4

Mounting plate kit - PCV-62-K8

Mounting plate kit - PCV-62-KEN

addtocart.popup.message.success

请求的数量已部分确认

产品 {0} 已在您的购物车中,数量为 {1} 。您可以从购物车页面更新数量

产品未激活

由于库存不足,无法将此产品添加到购物车

数量必须大于零

产品 {0} 允许的最小数量为 {1}

产品 {0} 允许的最大数量为 {1}

产品 {0} 的包装尺寸是 {1}

无法将代码 {0} 的产品添加到此购物车

出现错误,请稍后重试或联系客户支持

| 结构形式 | profile (with screws) and round tube (with tie-rods) |

| 设计 | ISO 15552 |

| 与介质接触的材料 | single and double-acting |

| 安装方式 | with front / rear flange, foot mounting, with front / rear / centre / swivel trunnion |

| 行程 | 10 ÷ 2500 mm |

| 工作温度 | standard and low friction: 0°C ÷ 80°C (with dry air -20°C) high temperatures (version W): 0°C ÷ 150°C (with dry air -20°C) low temperatures (version Z): -40°C ÷ 60°C (with dry air -40°C) low temperatures (version Y): -50°C ÷ 60°C (with dry air -50°C) |

| 存储温度 | 0°C ÷ 80°C (with dry air -20°C) |

| 可按要求定制特殊类型的产品 | 1 ÷ 10 bar (standard, high and low temperatures) 0,1 ÷ 10 bar (low friction) |

| 速度 | 10 ÷ 1000 mm/sec, no load (standard, high and low temperatures) 5 ÷ 1000 mm/sec, no load (low friction and uniform movement) |

| 介质 | filtered air in class 7.8.4, according to ISO 8573-1. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should never be interrupted. |

| 磁性接近开关 | model CSH |

CODING EXAMPLE

* Only for low friction

| 63 | M | P | 2 | C | 050 | A | 0200 | W |

| 63 | 系列 | |

| M |

VERSION M = standard, magnetic V = uniform movement (no stick slip), magnetic L = low friction, magnetic |

|

| P |

CONSTRUCTION T = round tube P = profile |

|

| 2 |

OPERATION 1 = single-acting, front spring 2 = double-acting 6 = double-acting, through-rod 7 = single-acting, through-rod 9 = single-acting, rear spring |

PNEUMATIC SYMBOLS CS07/CS18 CD08 - CD09 - CD10 - CD11 CD13 CS11 CS14/CS17 |

| C |

CUSHIONING N = no cushioning (mechanical endstops) C = cushioning on both sides F = front cushioning R = rear cushioning |

PNEUMATIC SYMBOLS CD08 CD09/CD13 CD11 CD10 |

| 050 |

孔径 032 = 32 mm 040 = 40 mm 050 = 50 mm 063 = 63 mm 080 = 80 mm 100 = 100 mm 125 = 125 mm |

080 = 80 mm 100 = 100 mm 125 = 125 mm |

| A |

CONSTRUCTIVE TYPE A = standard with rod nut RL = cylinder with rod lock |

DC = back to back cylinder with DC accessory [X1/X2] TR = back to back cylinder for round tube [X1/X2] F = cylinder with centre trunnion |

| 0200 |

STROKE = standard N = tandem / = more positions X1/X2 [X1<X2] |

|

| W |

TEMPERATURE RANGE = standard (-20°/+80°) W = high temperatures (150°C) |

Z = low temperatures (-40°C) Y = low temperatures (-50°C) |

|

RESISTANCE TO CORROSION = standard C1 = rod nut AISI 304 stainless steel, rod AISI 304 stainless steel C2 = end cap treated screws (profile) or AISI 303 tie-rods and AISI 420B tie-rods (round tube) |

C3 = C2 + AISI 316 rod nut, AISI 316 rod C4 = C1 + C2 C5 = C3 + end caps with triple protection |

|

|

ROD VARIATIONS = standard (male rod thread) F = female rod thread K = end caps with Kanigen treatment (only for corrosion resistance category C2, C3 and C4) L = without rod seal (rear air inlet only)* V = FKM rod seal R = NBR rod seal U = unlubricated operation |

H = hydrolytic environment A = use in food and other frequent washdown applications G = dry and dusty environments (with brass rod scraper and chrome-plated stainless steel AISI 420B rod) B = cylinder with NBR bellow rod protection (_ _ _) = extended rod _ _ _ mm |

|

|

OTHER P = cylinder with RAL 7035 polyurethane coating |

||

|

认证 EX = ATEX |

1-16/31 结果

马来西亚

马来西亚

样本下载

样本下载

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)